Equal Tee And Unequal Tee Carbon Steel Pipe Fitting Carbon Steel Tee

|

|

1/2" - 60" Carbon Steel Buttweld Seamless And Erw Pipe Fittings

Stainless steel size head application 1. Application in metallurgy and electric power industry Metallurgical and electric power industries need to consume a large number of metal pipes every year to transport coal powder, ash, mud, lime gypsum slurry, etc.Ceramic composite pipe is adopted to replace other pipes, which is characterized by high wear resistance, long service life, convenient installation and remarkable economic benefit. 2. Application in mining and coal industry (1) mine: mine filling, concentrate powder and tailings transport have seriously damaged the pipelines. The service life of the previously used powder conveying pipelines, such as panzhihua and daye mine, is less than one year. (2) coal: wet method is generally adopted for coal preparation and

long-distance pipeline transportation, which requires that the

conveying pipe is wear-resistant and corrosion-resistant, and can

be used as the long-lived conveying pipe with considerable economic

benefits.In the process of medium frequency heating boost, cut the

pipe to be processed into sections according to the required length

and cover the core rod;The inner core head foetus is made into a

round body member with a gradual section consistent with the

finished product, and it is connected with the core rod with a

detachable structure. The boost tube can be formed by moving along

the inner core foetus to one position.It enlarges the application

range of medium frequency heating boost manufacturing process,

simplifies the production process, and increases the variety to

meet the construction requirements. Seamless elbows do not cause corrosion, pitting, corrosion or wear.Stainless steel is also one of the strongest materials in building materials.Because stainless steel has good corrosion resistance, it enables structural components to permanently maintain the integrity of the engineering design.Rolling seamless elbow pipe materials are tubular billet, round tube embryo through cutting machine cutting the growth degree of billet is about one meter, and the conveyor belt to the heating furnace. Billet heating are fed into the furnace, the temperature is about 1200 degrees Celsius. In furnace temperature control is a crucial problem. Circular tube billet after go through pressure punch wear empty. Fuel for hydrogen or acetylene. General is one of the more common punch is tapered roller puncher, this kind of punch production efficiency is high, the products of good quality and large amount of perforated hole enlargement, can wear a variety of pipe fittings. After perforation, circular tube billet has been three-roll skew rolling, rolling or extrusion. Extrusion to take off the tube sizing. After sizing mill by taper drill bits high-speed steel into embryo punch, form fitting

|

|||||||||||||||||

| Product Tags: Carbon Steel Pipe Fitting Tee |

|

ASME 316L Stainless Steel Threaded Pipe Fittings Welded Elbow Customized Size |

|

Buttweld A234 Wpb B16.9 4Inch 45 Degree Steel Pipe Elbow Seamless |

|

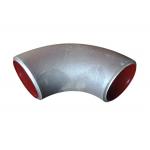

Rust Resistance 4inch Carbon Steel Elbow WPB 90 Degree Tube Elbow |

|

1/2-24INCH Seamless Tube Fittings Butt Weld Three Way Tee 1D-100D |

|

DN8~DN250 Customizable Stainless Steel Pipe Tee Fitting T Type Pipe Branch |

|

SS304 SS304L SS316 Metal Seamless Pipe Fitting Tee Sch5-Sch160 Thickness |