Seamless Pipe Fittings Mandrel Pushing 90 Degree 1/2-24 Inch A234 WPB

|

|

Mandrel Pushing 1/2-24 Inch A234 WPB 90 Degree Seamless Pipe Fittings Product Description: Two half elbow can be made in different material such as carbon steel , alloy steel and stainless steel . The quality is high .Firstly cutting the plate and heating the it . Then put the plate into the press machine to the elbow shape and after press and need to grinding or sizing again . At last we will do welding according to clients need .But most time ,the clients don’t need to do welding for convenience of transportation .

Product Show

Stainless steel size head application 1. Application in metallurgy and electric power industry Metallurgical and electric power industries need to consume a large number of metal pipes every year to transport coal powder, ash, mud, lime gypsum slurry, etc.Ceramic composite pipe is adopted to replace other pipes, which is characterized by high wear resistance, long service life, convenient installation and remarkable economic benefit. 2. Application in mining and coal industry (1) mine: mine filling, concentrate powder and tailings transport have seriously damaged the pipelines. The service life of the previously used powder conveying pipelines, such as panzhihua and daye mine, is less than one year. (2) coal: wet method is generally adopted for coal preparation and long-distance pipeline transportation, which requires that the conveying pipe is wear-resistant and corrosion-resistant, and can be used as the long-lived conveying pipe with considerable economic benefits.In the process of medium frequency heating boost, cut the pipe to be processed into sections according to the required length and cover the core rod;The inner core head foetus is made into a round body member with a gradual section consistent with the finished product, and it is connected with the core rod with a detachable structure. The boost tube can be formed by moving along the inner core foetus to one position.It enlarges the application range of medium frequency heating boost manufacturing process, simplifies the production process, and increases the variety to meet the construction requirements.

The size head (reducing pipe) is a fitting used for pipe diameters.The forming process usually adopted is reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing. A. Shrink/enlarge forming The reduction process of the size head is to put the tube blank which is equal to the diameter of the big end of the size head into the forming die.According to the diameter of reducing pipe, it can be divided into one pressing or multiple pressing. B. Stamping forming In addition to using steel tube as raw material to produce the size head, the size head of part of the specification can also be produced by stamping process of steel plate.The shape of the drawing die is designed according to the size of the inner surface of the head.

Contact me: Darcy Dong Whatsapp/ Wechat: 008615630731167 Guozhong International Limited |

|||||||||||||

| Product Tags: seamless buttweld fittings butt weld pipe fittings |

|

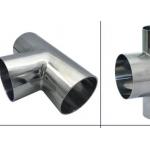

1/2-24INCH Seamless Tube Fittings Butt Weld Three Way Tee 1D-100D |

|

DN8~DN250 Customizable Stainless Steel Pipe Tee Fitting T Type Pipe Branch |

|

SS304 SS304L SS316 Metal Seamless Pipe Fitting Tee Sch5-Sch160 Thickness |

|

A234 Wpb Stainless Steel Tube Tee B16.9 Butt Weld Corrosion Proof |

|

ASTM B16.9 WP316L SCH40S 3 Inch Stainless Steel Pipe TEE Sch5S-Sch160S |

|

OEM OBM 1/2"-72inch Stainless Steel Equal Tee Buttweld Connection |