Product Description:

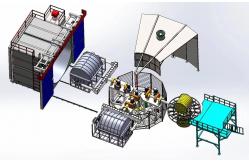

Rotational Molding Equipment is a multifunctional machine used for

creating a variety of water tanks and other products. It is made of

high-quality PE Plastic, and is powered by electric energy. The

machine also has a PLC (Programmable Logic Controller) as its

control system, and uses an air cooling mode to work efficiently.

Moreover, it is a rotary moulding machine, water tank making

machine, and rock and roll rotomoulding machines, making it a great

addition to any workplace. With the right care and maintenance, it

can last for years and produce high-quality products.

Features:

It only takes 3 minutes for the oven to increase the temperature

from room temperature (250 degree) to 280 degree. The arm is

constructed with an alloy material which is capable of withstanding

heavy load. This oven is equipped with a full-gear transmission,

guaranteeing high efficiency and full automation. This heavy-duty

oven not only provides excellent performance, but is also

energy-efficient. The mould can be easily loaded and unloaded. Its

special deep-cavity heating technology is suitable for complicated

product. It is also capable of internet-remote control should

problems arise in your factory. PLC and motors from Siemens, burner

from RIELLO, bearing from NSK, and electrical components from

Schneider are adopted in this oven. Moreover, it is equipped with a

big computer screen, bob-weight system, specially-made motor,

thermostability sealing arm head, etc. This oven, structured as a

circle, can ensure uniform heat distribution on the mould. This not

only facilitates product-making, but also saves energy.

Technical Parameters:

| Parameters | Details |

|---|

| Material | PE Plastic |

| Control System | PLC |

| Type | Rotational Molding Equipment |

| Heating Mode | Electric Heating |

| Size | Customized |

| Cooling Mode | Air Cooling |

| Temperature | High |

| Voltage | 220V, 400V |

| Key Selling Points | Multifunctional |

| Warranty | 1 Year |

| Usage | Water tank making machine, rotary moulding machine, rotary moulding

machine suppliers |

Applications:

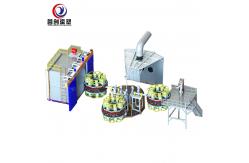

Rotational Molding Equipment, with brand name Yingchuang, is

manufactured in Jiangsu, China, and is CE certified. It is

available with a minimum order quantity of 1, and is packed in

wooden boxes with packaging cotton. Delivery time is less than

40-60 work days, and Yingchuang is able to produce 2-3 machines per

month. The equipment also comes with a 1 year warranty. It features

electric heating and air cooling technology, and is available as a

customized size and power.

Rotational Molding Equipment is widely used for a variety of

applications, such as the production of water tanks, automobile

parts, as well as the manufacture of shuttle rotomolding machines.

It is ideal for large-scale production, as it is able to produce

large quantities in a short time. It is also highly efficient and

cost-effective, and requires minimal manpower for operation.

Rotational Molding Equipment is a reliable and durable solution for

various industrial applications. It is designed to meet the highest

standards of quality and performance, and is equipped with the

latest technology for optimal results. It is easy to use and

maintain, and offers maximum safety and convenience.

Customization:

Custom Rotational Molding Equipment

Brand Name: Yingchuang

Place of Origin: Jiangsu, China

Certification: CE

Minimum Order Quantity: 1

Packaging Details: Wooden box, packaging cotton

Delivery Time: Less than 40-60 work days

Supply Ability: Can produce 2-3 machines per month

Service Life: Long

Temperature: High

Voltage: 220V, 400V

Cooling Mode: Air Cooling

Type: Rotational Molding Equipment

Our rotational molding equipment is perfect for water tank

manufacturing. It is a durable and long-lasting machine that can

handle high temperature and voltage. It features air cooling and

comes with CE certification. We offer fast delivery and can produce

2-3 machines per month.

Packing and Shipping:

Packaging and Shipping for Rotational Molding Equipment:

- The equipment will be securely packaged and shipped to the

customer's site.

- Equipment will be checked against the customer's order prior to

shipment to ensure accuracy.

- Packaging will be designed to provide adequate protection for the

equipment during shipping and handling.

- The equipment will be tracked throughout the entire shipping

process.

- The customer will be provided with a tracking number for the

shipment.