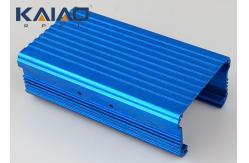

Anodized Painted CNC Rapid Prototyping Al 6063 Passivating

|

|

Custom anodized and painted aluminum alloy CNC milling industrial auto parts

Basic information:

KAIAO has an excellent team focusing on product development, design, quality control, inspection, and company operations. In order to provide customers with satisfactory products and services, KAIAO has established a modern quality management system in strict accordance with international standards. KAIAO's vision is to become a leader in the CNC industry. Whether

choosing OEM, ODM services, or seeking engineering help for

application, customers can discuss the procurement needs or any new

ideas for the product with KAIAO’s service center. Main Materials:

Surface Finish:

Products packaging:

1. With plastic bag,with pearl-cotton package. 2. To be packed in cartons. 3. Use glues tape to seal cartons. 4. Deliver out by DHL,FEDEX,UPS. Or according to customers' requirement. Injection molding packaging: Standard wooden case,and pallet, suitable for shipment, to avoid damaging,or according to customer's requirement.

Quality Control: 1. Checking the raw material after they reach our

factory------- Incoming quality control ( IQC) 2. Checking the details before the production line operated 3. Have full inspection and routing inspection during mass

production---In process quality control(IPQC) 4. Checking the goods after they are finished---- Final

quality control(FQC) 5. Checking the goods after they are finished-----Outgoing

quality control(OQC) Quality Control Standards: In order to live up to the trust of our customers, quality control

and assurance is achieved through 1. Comprehensive written procedures and policies; 2. Details

records of incoming raw material 3. Analysis of root cause of non-conformances 4. Fully equipped inspection department 5. Consistent calibration and labeling of inspection tools |

||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Anodized Painted CNC Rapid Prototyping Al 6063 CNC Rapid Prototyping Passivating CNC Milling Auto Parts |

|

Milling Processing CNC Rapid Prototyping Turning Metal Parts ISO 14001 |

|

Anodized CNC Rapid Prototyping CNC turning milling parts Metal Parts Processing |

|

Rapid Prototyping Injection Molding Plastic Parts OEM Service Extrusion Molding Parts |

|

Micro Machining CNC Lathe Parts Stainless Steel Aluminum Alloy Milling Machine Processing |

|

Custom OEM Precision Aluminum CNC Machining Parts Stainless Steel CNC Machining Parts |

|

OEM Metal Zinc Aluminum Alloy Custom Die Casting Parts Precision |