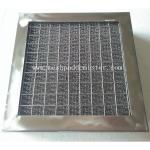

SS304 750mm Cellular Structure Stainless Steel Knitted Wire Mesh

Demister Pad

The demister safely functions because the design adapts to changes

in gas or fluid flow rate. Generally, the 100mm mesh pad is used,

but the mesh pad of greater thickness is used where the flow rate

changes extensively, offering increased production.

Though the demister is deemed the standard type because it is used

in many fields, this model is strong and highly efficient. The

demister is used in places where it is necessary to reduce

accompanying airborne droplets to a minimum. Demister pad vapor liquid separator Specifications 1. Material SS3042. Shape & Size Φ750 mm3. Mesh Thickness 100 mm4. Demister Height 150 mm5. Wire Diameter 0.28 mm6. Mesh Density 176 kg/m37. Void Fraction 0.9788. Specific Area 315 m2/m39. Grids Flat bar 25*3mm Applications of demister pad 1. SS304 Water solutions, Nitric acid reduced crude petroleum

fraction etc.2. SS316L Fatty acid reduced crude containing naphthenic acids and

corrosive chemicals3.3. Synthetic fiber For corrosive service at moderate temperature4. PP(Polypropylene) For corrosive service at temperature up to 70℃5. PTFE For corrosive service at temperature of (-190℃, 250℃)6. Monel Caustic soda, dilute acid7. Nickel Caustic Soda, food products8. Copper Freon, alcohol9. Aluminium Nitric Acid How do demister pad mist eliminators work?When a vapor stream carrying entrained liquid droplets passes

through the EIT Mesh but the inertia of the droplets causes them to

contact the wire surfaces and be held there briefly. As more

droplets collect, they grow in size, run off and fall free.

Properly applied to specific process conditions, DEMISTER mist

eliminators achieve 99.9% separation of liquid entrainment from any

vapor stream, assuring pure product overhead. Pressure drop is

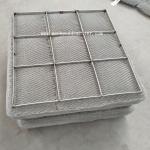

usually less than 25.4 mm H2O (1" WC). Numberous cases of demister mist eliminator we ever made in Hualai

factory:

Welcome your inquiry with any questions! Here in Hualai we are

always ready to be helpful!

|