Salt Evaporator Use Vane Pack Mist Eliminator 2205 Material

|

|

Salt evaporator use vane pack mist eliminator 2205 material

1. Vane Pack mist eliminator datasheet:

2. Vane pack mist eliminator working process:

when the gas containing mist flows through the vane pack mist eliminator at a certain speed, because of the inertial impact of the gas, the mist and wave plate collide and are attached to the wave plate surface. The multi fold structure of the wave plate of the mist eliminator increases the chance of catching and gathering the mist, and the undeleted mist will catch and gather at the next turn through the same function, so it will work repeatedly, thus greatly improving the efficiency of mist eliminator. After the gas passes through the chevron mist eliminator, there is basically no mist.

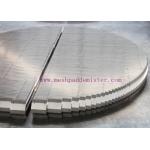

3. Vane pack mist eliminator structure:

The vane pack mist eliminator consists of a set of chevron corrugated plates with well defined geometry. It is very popular and useful internals for gas liquid separation applications. These plates according to design and shape can remove the droplets more than 8 microns. Hualai factory has been producing a range of vane pack mist eliminators for critical applications in industrial use. Standard Material of vane type mist eliminator is polypropylene & stainless steel.

4. Advantages of Hualai vane pack mist eliminator / chevron plate demister:

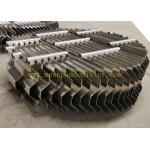

Mist droplets are thrown out of the gas by multiple gentle angles, minimizing disruptive eddies at the corners. Metal plates are held by equal-space slotted frames. We care about the details for each application.

When you walk on the finished vane pack mist eliminator, you can feel its strength and stiffness. Thicker plates resist fluttering and last longer in corrosive and erosive service. It requires little maintenance after installation in the vessels.

Gentle angles of the plate means lower pressure drop than those with sharp corners and drainage hooks. It makes great difference especially in some applications such as vacuum towers.

Less turbulence around the corners also means minimal re-entrainment of liquid draining down the plates. Usually for droplets with diameter 20 microns and larger, the removal efficiency is over 90%; and for 40-micron and larger droplets, the removal efficiency can be 99.9%.

It allows higher gas velocity than mesh pad demister without losing efficiency due to re-entrainment.

The most common construction materials are carbon steel and 304 and 316 stainless steel. But we understand your corrosion requirements and can provide other alloys or nonmetallic construction as per order.

For PP material, vane plates with small hook is available for option. And for stainless steel material, vanes can be welded with short extensions hooks from one or more corners. That style is preferred by some users to help prevent re-entrainment of liquid.

5. Vane Pack Mist Eliminator Cases:

Removal of very small droplets can be achieved using a two stage mist eliminator by fitting a mesh pad to the upstream face of the unit to coalesce droplets as small as 4 to 5 microns into droplets in the size range which are easily removed by the vane separator.

Welcome your inquiry anytime! We are ready to provide any possible help we can!

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 2205 Vane Pack Mist Eliminator Vane Pack Mist Eliminator 2205 salt evaporator Vane Pack Mist Eliminator | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4000mm Plus Stainless Steel Corrugated Plate Mist Extractor Separator Eliminator |

|

300mm Diameter Spacer Ribs Ss304 Vane Pack Mist Eliminator |

|

316l Vane Plate Wire Mesh Mist Eliminator With Custom Hooks / Frames |

|

316 L Chevron Demister Mist Eliminator Filter Custom Plate Shape And Spacer |

|

SS304 Laser Cut Ribs Custom S Type Chevron Mesh Pad Mist Eliminator |

|

30mm Vane Distance Chevron Plate Vane Pack Mist Eliminator 316L |