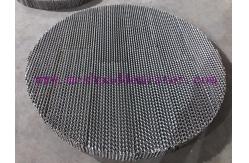

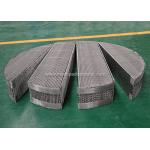

3y Corrugated Metal Plate Distillation Packing

|

|

3Y corrugated metal plate distillation packing specific surface area

1. corrugated metal plate distillation packing popular types. (please contact me for more custom types)

Note: The influence of opening rate on the plate is not calculated

2. corrugated metal plate distillation packing manufacturing requirements

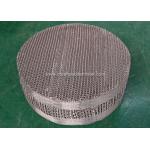

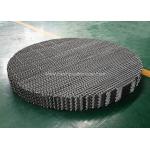

2.1 According to the requirements, punching, rolling fine grain (or rolling grain equivalent to fine grain) and corrugation of raw stainless steel belt shall be made into corrugation belt of orifice plate, and then the corrugation plate shall be cut into pieces according to different chord length on the cross section of packing plate and the requirements of packing plate assembly or block assembly. 2.2 The packing plate is composed of a number of corrugated plates arranged vertically and evenly. The corrugation angle of the two adjacent orifice plates is overlapped in the opposite direction. 2.3 According to the design of tower equipment, the packing plate can be made into a whole plate or block type. The purpose of block type is to facilitate the installation of packing. Each block size shall be able to enter the tower from the manhole for assembly. For towers with a diameter less than 800mm, they can be manufactured as a whole tray or into blocks. 2.4 The whole disc of packing shall be tightly clamped with steel belt, and the end of the hoop shall be lapped and spot welded to prevent the packing from deformation. After the upper hoop is installed, the upper edge shall be cut and reserved for the flanging before the packing is installed in the tower, and the hoop shall be made into the form of anti wall flow ring. For the block packing, the packing block close to the tower wall shall be made into the form of anti wall flow ring at the end close to the tower wall. The gap between the slits depends on the diameter of the tray, and it shall be close to the tower wall. 2.5 For block packing, block diagram shall be drawn. The packing block with the same size and specification in the drawing is called "standard block", and the packing block with other sizes is called "non-standard block". There are three methods to construct the packing block: nailing through, spot welding and combination of both. 2.6 The packing of the whole disc or the packing blocks shall be arranged evenly, and the disc surface shall be flat without unevenness.

3. Function of corrugated metal plate structured packing in distillation column

4. What are the necessary conditions for high vacuum distillation column?

1) The surface area per unit volume of structured packing should be

large;

every year we manufacture and supply hundreds of cubic meters of metal structured packing in different models. There are many popular types and materials for option. Custom order is welcome, too! We are happy to help with what you need! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: corrugated metal plate distillation packing 3y distillation packing distillation packing 3y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3000 Mm Distillation Packing Corrugated Metal Plate 316l Stainless Steel 450y |

|

Tower Internal Dia 1100mm Distillation Packing Operation Flexibility 60% - 120% 250y |

|

Cy 700 Type Wire Mesh Structured Packing Dn 800 Mm * 12000 Mm Height |

|

2.5m * 2.5m * 3m Height Distillation Packing Metal Perforated Plate 304 250y |

|

Dn 1600 * 100 Mm Height Distillation Packing Ss 304 Cy 700 Wire Mesh |

|

SUS 304 Distillation Column Packing Material 970 Mm * 440 Mm *100 Mm Size Mella 350Y |