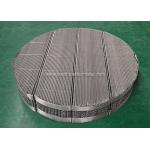

BX Stainless Steel Metal Structured Packing Fine Chemical Tower Internal

|

|

BX Stainless Steel Metal Structured Packing Fine Chemical Tower Internal

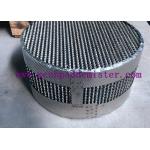

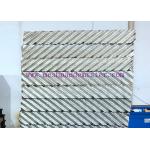

Metal Wire Mesh Corrugated Packing consists of vertically arranged corrugated wire mesh sheets, which are usually 100 mm, 150 mm and 200 mm in height. Other heights can be customized. The direction of the ripple is opposite to that of the adjacent ones, and the inclination angle against the tower axis is 30 or 45 degrees. The diameter of packing tray is several millimeters smaller than tower inner diameter. The packing tray fills the section of tower precisely. The outer hoop of each packing tray can be flanged to prevent wall flow, and the two adjacent trays rotate 90 degrees to install. The main materials of corrugated wire mesh packing are stainless steel, copper, aluminium, low carbon steel, nickel, titanium, etc.

wire gauze structured packing is the preferred packing in distillation service for deep vacuum and low liquid rate applications. The characteristic of lowest pressure drop per theoretical stage makes wire gauze packing the preferred device for processing specialty chemicals, pharmaceuticals and temperature-sensitive materials. Wire gauze packing is generally used in small to medium diameter columns to achieve the maximum number of theoretical stages in the minimum column height. Because of the capillary effect, the wire mesh material provides an extremely wettable surface resulting in excellent mass transfer efficiency particularly at very low liquid rates.

wire mesh structured packing products list (normal):

①The data are based on 0.12mm wire, stainless steel material. Applicable temperature (-200—400)℃. 0.15mm and 0.17mm wire are also available. ②Metal wire mesh corrugated packing is suitable for clean gas-liquid system without solid particles or suspended solids or not easy to self-assemble.

Projects applying wire mesh structured packing

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: wire mesh packing structured packing distillation column |

|

Bx500 Type 200mm High Wire Mesh Structured Packing Stainless Steel 316l |

|

316l Stainless Steel Column Packing 250y 0.15mm Sheet Structured |

|

500Y SS316L 400mm Diameter Metal Structured Packing |

|

1500mm 100mm M125Y Structured Packing In Washing Tower |

|

Layer Height 150mm Rectangular Shape Metal Structured Packing |

|

410s M125Y Metal Structured Packing Layer Height 200mm |