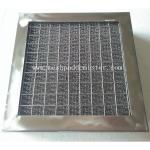

1400mm Round Demister Pad 511

|

|

1400mm round demister pad made in Hualai 511 mesh type experiences The gas / vapor containing droplets passes into mesh pad demister at a predetermined velocity. It easily finds open path through the mesh but the droplets and mist impinge on the filaments of mesh where they coalesce and eventually grow to such a size to overcome surface tension of liquid and force of gravity. Then the liquid droplets so formed fall down. And the mist free gas / vapour passes through the mesh demister pad.

How do demister pads mist eliminators work?

When a vapor stream carrying entrained liquid droplets passes through the EIT Mesh but the inertia of the droplets causes them to contact the wire surfaces and be held there briefly. As more droplets collect, they grow in size, run off and fall free. Properly applied to specific process conditions, DEMISTER mist eliminators achieve 99.9% separation of liquid entrainment from any vapor stream, assuring pure product overhead. Pressure drop is usually less than 25.4 mm H2O (1" WC).

Where are DEMISTER units used?

Knockout drums and separators – save on capital costs by decreasing vessel size-recover costly fatty acids from stream-reduce compressor maintenance by preventing scale build-up. Absorbers – reduce overhead losses of glycols in dehydrators to no more than 0.1 gal/MMSCF natural gas-cut losses of absorption oil and amines in CO2 systems. Scrubbers – reduce chemical discharges from Kraft mill smelt dissolver tank to less than 0.11 kg/dry ton (0.25 lb/dry ton) of pulp-improve scrubber efficiency by removing particulates carried in entrained liquids. Distillation columns – improve product purities and increase throughput capacities for petrochemicals, organic intermediates, fine chemicals. Evaporators – prevent carryover loss of valuable products, keep condensate TDS <10 ppm for highest quality boiler feed water-clean up vacuum ejector stream discharge-lower maintenance in vapor re-compression systems. High pressure steam systems – provide dry steam- cut TDS to <10 ppb in condensate-eliminate build-up on turbine blades. Refinery towers – increase throughput capacity-take deeper cuts for greater product yields – prolong catalyst life in downstream cracking and reforming units by reducing carbon and metals in side draws-use lower grade crudes.

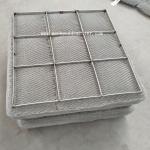

Hualai’s Advantages in mesh pad demister:

Optimized solutions Standard configurations Tailored made configurations Expedited services available knowledge and engineering experience High quality manufacturing standards and procedures Manufactured in a variety of corrosion resistant materials (Metals, Plastics and Co-knit mesh options)

Located in Anping, China, we enjoy many advantages like convenient material purchasing, lower labor cost, faster courier service, etc. Demister Material we usually use: PP, PTFE, SS304, SS304L, SS316, SS316L, SS201, SS202, SS301S, SS321, Copper, Nickel, Titanium, Duplex 2205, Duplex 2507, NS-80, Monel 400 alloy, Co-knit 904L+fiber glass, Co-knit 316L+ fiber glass, Co-knit 316L+PP flat... |

||||||||||||||||||||||||||||||

| Product Tags: wire mesh demister pad wire mesh pad |

|

Pp Donut Shape Demister Pad Diameter 3000mm 1000mm |

|

Ss304 Demista Pad Length 1100mm Width 450mm Knitted Mesh |

|

Ss310 Mesh Pad Mist Eliminator Square Shape Drain Hole Steel Wire |

|

PTFE F4 Diameter 900mm Demister Pad Height 200mm Round Shape Knit Mesh |

|

Ss316l 1100x450mm Rectangle Mesh Pad Demister |

|

Ss316 600x600mm Wire Mesh Demister OEM Design |