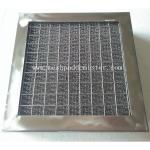

High Voidage Titanium Demister Pad

|

|

High Voidage Titanium Demister Pad + Ti Grids Flat Bar HL-Ti 99% Filter Rating

The Ti mesh demister pad is designed to collect liquid particles contained in the vapour phase after boiling, vacuum evaporation or bubbling process. Small droplets in the gas contact the wide surface of the filaments of the mesh pad demister, gradually grow into large liquid droplets and flow and drop by a special structure accelerating the coalescing of the liquid droplets. The mesh pad of the demister is highly porous, so the vapour gas passes through the demister without hindrance, leaving only pure gas. The process is not a type of filtering as the hole size of the knit mesh is not specially related to the size of the liquid droplets. This mist elimination is caused by the collision and sudden change resulting from the flowing speed of the small liquid droplets, and the coalescing of the liquid drips and gravity cause their descent. This is a process combing mechanical and physical phenomenon.

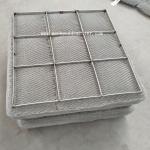

Case study of Ti (Titanium ) wire mesh demister pad we made:

What can Hualai factory do for you in the Ti mesh demister pad?

1. Hualai demister pad is tailor made to suit for specific vessel dimensions and configuration. 2. Hualai provides wide variety of material to suit for even the most corrosive process environments. 3. Hualai factory can supplies either mesh pad only, or complete demister with top and bottom supporting grids for direct installation in vessels. 4. Sectional construction for easy handling and access through man ways. 5. Complete accessory pack including support ring and beam can be provided when required.

Applications of Ti mesh demister pad:

Reduce loss of valuable chemicals: demister pads markedly cut glycol, amine, or solvent consumption in absorption and regeneration towers. Increase throughput capacity: demister pads allow a significant increase in throughput anywhere gases and liquids come into contact in process equipment. Improve product purity: demister pads prevent contamination of side draws and overheads in refinery atmospheric and vacuum towers and other distillation columns. Minimize contamination: demister pads can prevent the poisoning of expensive downstream catalysts or provide boiler feed water quality condensate from evaporator overheads. Provide equipment protection: demister pads protect turbine, blower, and compressor blades, which can eliminate serious maintenance problems. Reduce air pollution: demister pads help diminish droplet emissions to environmentally acceptable levels.

|

||||||||||||||||||||||||||||||

| Product Tags: wire mesh demister pad wire mesh pad |

|

Pp Donut Shape Demister Pad Diameter 3000mm 1000mm |

|

Ss304 Demista Pad Length 1100mm Width 450mm Knitted Mesh |

|

Ss310 Mesh Pad Mist Eliminator Square Shape Drain Hole Steel Wire |

|

PTFE F4 Diameter 900mm Demister Pad Height 200mm Round Shape Knit Mesh |

|

Ss316l 1100x450mm Rectangle Mesh Pad Demister |

|

Ss316 600x600mm Wire Mesh Demister OEM Design |