SS316L Structured Packing Corrugated Metal Sheet Corrugation Surface Treatment

|

|

SS316L Structured Packing Corrugated Metal Sheet Corrugation Surface Treatment

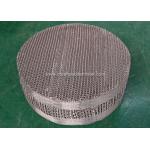

Materials of Construction

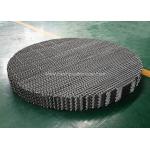

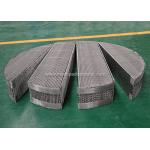

The most common material used for structured column packing is SS 304L and SS 316L. However manufactures this solely based on our customers’ requirements and can also be made from other materials based on special requests. Uniform Liquid Distribution In order to achieve even liquid distribution over the packing it is a must to have a good liquid distributor to maximize the interaction of the liquid and vapor. However if the packing height exceeds 3 meters we recommend using an intermediate liquid re-distributor as well for even flow. structured packing uses the industry standard corrugated perforated and embossed sheet metal design to provide efficient vapour-liquid contact. The style of the embossed surface has been optimised to provide maximum wetability and numerous perforations enhance cross mixing of the process fluids. Type Y has a crimp angle of 45° and type X 30°. Suitable liquid irrigation range from below 0.5 up to 200 m3/m2.hr.

structured packing products list (part):

Benifits of structured packing:

Lower pressure drop through the column ■Lower botoms temperature for heat sensitive systems ■Higher relative volatility for difficult separations ■Lower energy consumption ■Reduced foaming tendency Higher efficiency in the same tower height ■Large number of theoretical stages required ■Reduced reflux requirement Higher capacity ■Reduced vessel diameter ■Increased operating rates Excellent liquid spreading characteristics ■Improved efficiency ■Offshore applications subject to permanent tilt and motion Reduced liquid hold-up ■Smaller amounts of polymer inhibitor

Surface Treatments of Sheet Metal Structured Packing

It is important to achieve good contact between the liquid and vapor phases. A packing that spreads the liquid evenly in a thin film will exhibit beter performance. Mixing the film creates turbulence that enhances the mass transfer. Modifications to the texturing of the packing surface improve the liquid spreading which, in turn, leads to enhanced packing efficiency. All types of structured packings are available in a variety of corrugation sizes. This provides the versatility needed to optimize a packing configuration to best meet the efficiency, capacity, and pressure drop requirements for a particular application.

Welcome your inquiry about structured packing any time! |

||||||||||||||||||||||||||||||

| Product Tags: structured packings structure packing in distillation |

|

3000 Mm Distillation Packing Corrugated Metal Plate 316l Stainless Steel 450y |

|

Tower Internal Dia 1100mm Distillation Packing Operation Flexibility 60% - 120% 250y |

|

Cy 700 Type Wire Mesh Structured Packing Dn 800 Mm * 12000 Mm Height |

|

2.5m * 2.5m * 3m Height Distillation Packing Metal Perforated Plate 304 250y |

|

Dn 1600 * 100 Mm Height Distillation Packing Ss 304 Cy 700 Wire Mesh |

|

SUS 304 Distillation Column Packing Material 970 Mm * 440 Mm *100 Mm Size Mella 350Y |