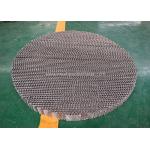

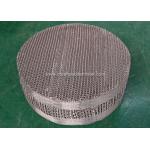

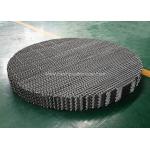

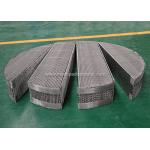

316L Metal Distillation Corrugated Structured Packing For Drying Tower

|

|

316L Metal Distillation Corrugated Structured Packing For Drying Tower

Metal wire mesh packing is the most widely used high efficient filter in the world at present. Its main advantages are: ü High number of theoretical plates, large flux and low pressure drop; ü Good performance with low working load, increased number of theoretical plates with the decrease of gas load, and there is almost no bottom limit of work load; ü Large operation elasticity; ü No obvious amplification effect; ü Fulfilling the requirements of precision, large and high vacuum distillation units, providing favorable conditions for distillation separation system, heat sensitive material and high purity products. More applications of metal wire mesh structured packing: Mass transfer of temperature sensitive chemical products Proper lateral distribution of liquids and gases Solvent recovery Batch and continuous distillation Low liquid loading systems Providing highest theoretical stages per meter of packing height Reducing liquid hold up Economizing operating loads of vessels |

| Product Tags: wire mesh pad mesh mist eliminator |

|

3000 Mm Distillation Packing Corrugated Metal Plate 316l Stainless Steel 450y |

|

Tower Internal Dia 1100mm Distillation Packing Operation Flexibility 60% - 120% 250y |

|

Cy 700 Type Wire Mesh Structured Packing Dn 800 Mm * 12000 Mm Height |

|

2.5m * 2.5m * 3m Height Distillation Packing Metal Perforated Plate 304 250y |

|

Dn 1600 * 100 Mm Height Distillation Packing Ss 304 Cy 700 Wire Mesh |

|

SUS 304 Distillation Column Packing Material 970 Mm * 440 Mm *100 Mm Size Mella 350Y |