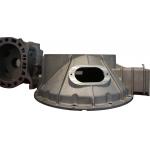

Multi Cavity Aluminum Casting Mold For Accessories

|

|

Custom High Precision Multi Cavity Aluminum Casting Mold for Accessories

So far, we have 6 invention patents, 20 patents for utility models. It is a famous trademark enterprise in Henan Province. The company has more than 230 employees, including 36 professional mould design engineers and 39 senior technicians; We have 40 sets CNC machines and 28 sets general machines, 2 sets of 3D Coordinate Measuring Machines, 1 set of reverse scanner. Adopting the computer three-dimension design, programming, computer-aided processing technology, and the FM method to cast the aluminum mould blank, and combining with the original surface treatment technology of , all aspects of our mould has been reached the industry leader such as quality, precision, efficiency, service life and so on.

FAQ: 1. Q: What is the processing for the quote? 3. Q: What is the software will you use for the proceeding? Aluminum Die Casting Applications: Aluminum castings improve automotive fuel efficiency by

contributing to weight saving requirements

Pressure Casting Mould Features

Manufacture Process

Our Advantages

|

||||||||||||||||||||

| Product Tags: Multi Cavity aluminum casting mold HRC45 aluminum casting mold ODM aluminum casting mold |

|

Heat Treatment Sand Casting Mould Clutch Housing |

|

Cylinder Block Hot Core Box Sand Casting Mould Customizable |

|

Aluminum Clutch Case Sand Molded Casting Low Pressure |

|

Customizable High Precision Aluminium Sand Casting Mould Sand Mold Casting |

|

Precision Aluminum ADC12 ADC14 Sand Casting Mould Heat Treatment |

|

A360 A380 Green Sand Casting Annealing Quenching Heat Treatment |