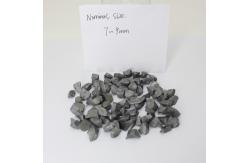

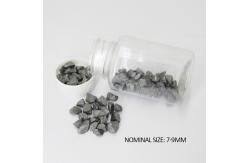

7-9mm YG YD Tungsten Carbide Particles Black Crashed Grits

|

Detailed Product Description

Description of Carbide Crashed Grits:

Szie Chart of Carbide Crashed Grits:

Application of Carbide Crashed Grits:

The tungsten carbide grits is suitable for hard facing material. 1 mesh to 12 mesh: used for wear-resistance electrode and mace electrode; 10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

Advantages of Carbide Crashed Grits:

|

| Product Tags: YD Tungsten Carbide Particles 9mm Tungsten Carbide Particles Tungsten Carbide Black Crashed Grits |

Related Products

|

Irregular Tungsten Carbide Particles for Wear-resistant Surface Pre-strengthening in Agricultural Machinery and Steel |

|

100% Purity Tungsten Carbide Powder for Optimal Results in Industrial Processes |

|

Tungsten Carbide Particles Support Customized Particle Size AS PER CUSTOMER REQUIREMENTS Logo 1.6-3.2mm Grit Diameter |

|

Customized Particle Size Tungsten Carbide Particles Carbide Alloy Particle for Petroleum Processing |

|

0.3-9.5mm Cobalt Cemented Tungsten Carbide For YG7/93%WC And 7%Co Alloy 100% Purity Guaranteed |

|

3-5mesh Tungsten Carbide Particles Grit Diameter 1.6-3.2mm Alloy Specification YG7/93%WC And 7%Co |

Email to this supplier