High Speed PLC Control Paper Roll Slitting and Rewinding Machine Paper slitting machine is a paper processing equipment that cuts

and rerolls wide web paper into coils of varying width and

diameter. Widely used in paper processing industry or pre - and

post-press mechanical equipment.

Features - Paper scutters adopt PLC and touch screen control, magnetic powder

clutch tension control and center coiling mode.

- The host adopts frequency conversion for speed regulation. Can

automatically meter, alarm stop. The tension numbers are all

displayed on the touch screen.

- Unwinding adopts photoelectric automatic correction (or ultrasonic

correction) to correct the paper edge neat, so that irregular

materials can be normally sundered.

- Circular knife (or straight knife) cut lengthwise, waste edge

automatic discharge device.

- Manual (or pneumatic) feeding reel with cone sleeve air expansion

shaft (3 "or 6").

- Winding A, B axis (air expansion type)

Main structure and working principle Paper slitting machine is composed of frame, transmission system,

retracting and retracting machinery and tension control device,

traction component, slitting support, waste rewinding and discharge

device, etc. It is the raw material is cut into a number of

independent units, its working principle is the raw material is

fixed on the feeding shaft on one end of the magnetic powder

tension controller to maintain the tension required by the raw

material, and then through a pair of rubber roller to pull the raw

material, cut into a number of blades. Then through the guide

roller guide to A, B reel winding finished products. Its drive is

driven by the main motor traction rubber roller and the receiving

shaft synchronous operation to achieve the purpose of traction and

finished materials. Frame and transmission system: the frame is composed of left and

right wall panels, braces and feeding machinery. Drive system is

mainly used for drawing materials, winding, it is by the frequency

conversion stepless speed regulating motor power through motor

traction roller operation of V belt, the main rubber roller and the

driven traction roller is clingy and synchronous operation traction

walking raw material, through active traction roller driven

circular knife axis synchronous operation and achieve better

cutting requirements, Through the lower round tool shaft drive

winding A and winding B synchronous operation, so as to achieve the

purpose of material. Material receiving mechanism and tension device: the material

receiving mechanism is mainly composed of chain, synchronous wheel,

magnetic powder clutch, and air expansion shaft and other parts. By

a separate motor control two reel operation, as long as the

magnetic powder clutch current adjustment, can change the size of

the tension of the receiving shaft. Traction component: the traction component is mainly composed of a

pair of traction cots and a number of hard oxidized aluminum

rollers, which play a role in retracting raw materials for winding

finished products. Its power comes from the motor through the

V-belt transmission to the active traction cots to make it run. Cutting tool rack: cutting tool rack with round knife cutting,

straight knife cutting. The operating handle can adjust the shear

clearance between the round blade mouth and the cushion sleeve

groove by making the round knife move slightly axial through the

plane CAM. Waste winding and discharge: waste is discharged through the air

duct using the wind power of the blower. Feeding mechanism and automatic rectifying: feeding mechanism

mainly has feeding shaft, support block, cylinder, base, left and

right moving seat and other components of automatic rectifying

device: photoelectric start, rectifying guide roller, left and

right bracket, rectifying moving plate, ball nut and screw,

synchronous motor and left and right limit switch.

Machine installation and use adjustment

After the machine is unpacked, the integrity of the machine should

be checked to check whether there is any damage during

transportation, etc. After the inspection, the calibration level

can be installed on a smooth and solid foundation. After the

machine is installed and calibrated, check whether all parts are

intact, whether the connection bolts are tightened reliably, and

whether the movable parts are flexible. Then fill the corresponding

lubricating oil in each lubricating part, check the refueling and

confirm no error before starting the machine. Before starting the

machine, read the instruction manual attached with the machine

carefully. Start slowly, and then slowly increase the cutting speed

until it reaches normal.

Technical specification

Parent Roll Width | 2200mm | Parent Roll Diameter | 1350mm | Paper Basis Weight | 60-800g | Minimum Slitting Width | 50mm | Slitting Roll Diameter | 1300mm | Machine Speed | 200m/min | Loading mode | Hydraulic (Shaftless) | Unloading mode | Automatic | Rewind type | Single Shaft φ76.2mm | Break mode | Air-manual | Adjustable cutter positioning | Semi-automatic | Length(m) count mode | Automatic | Clamp taper head | Standard 3 inch (6/8/12 selectable) | Slitting knife | 20 sets | Speed control | Frequency control | Input voltage | 380V (3p) |

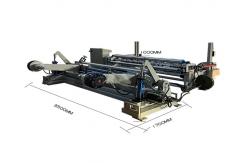

Machine Photo

|