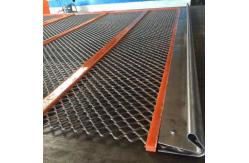

Wire Ripple Screen Vibrating Screen Wire Mesh Anti - Pegging

|

|

Wire Ripple Screen IS AVAILABLE IN HIGH TENSILE STEEL MESH OR STAINLESS STEEL.

Self-cleaning screens are a non-blinding, high quality screening surface that provides accurate screening and sizing. Having many advantages over other screen types, self cleaning mesh gives higher production rates while eliminating the problem of Large unwanted flat material that contaminates the finished product.

THE BENEFITS Anti-clogging Anti-pegging Increased wear life Accurate sizing Available to suit all types of mobile and static screens With high quality, non-blinding screening surface the Flexi-Harp is the perfect mesh. The combination of different size wire used in manufacture means that they vibrate at varying frequencies to produce a self-cleaning surface. Due to its flat surface (no knuckles Self-cleaning screens can use a smaller wire diameter than woven wire for some applications. Separates flakes and slivers from finished product while greatly reducing problems like plugging and blinding.

Depending on the placement of the wavy wires and their connection type we can divide harp screens Into following categories:

Progress Harp Type K This type of screens is made of round wavy, wires, curved in the horizontal working plain. Angle between the arms equals 90.

Working size of W opening is created by diameter of the circle written into this opening. Wires placed one next to another create openings similar to a square. Working wires are buckled together with transversive wires using polyurethane, rubber or wires inside plastic cover.

Progress Harp Type T They are produced with wires of round diameter – straight and wavy placed alternately on the horizontal working surface. Wave spread span equals 90 or 60 . Working size of W opening is created by the diameter of the circle written into this opening. Straight, round wires have a slightly larger diameter then wavy ones. This series of screens characterizes with high ability to withstand heavy loads (owing to very well stretched straight wires)and good self-cleaning effect, obtained by self – oscillation of wavy wires. Wires in this series of screens can be connected with each other using wire knots, polyurethane, rubber or transverse wires inside plastic cover. Huatao Lover Ltd. TEL:+86-311-80690567 Mobile Phone: +8613331385676 (same number with WhatsApp and Wechat) Email : maple@huataogroup.com |

| Product Tags: vibrating screen wire mesh pu screen mesh |

|

HT2036 High Precision Rectangular Gyratory Sifter For Quartz Sand Screening |

|

Microporous Alumina Ceramic Vacuum Plate For Mining Industry Dewatering |

|

6M2 Porous Ceramic Filter Plate For Mining Industry Dewatering |

|

12M2 Ceramic Filter Plate For Mineral Soild Liquid Separation |

|

Tailings Solid Liquid Separation 4M2 Ceramic Filter Plate |

|

High Precision 3 M2 Ceramic Filter Plate For Mining Tailing Dewatering |