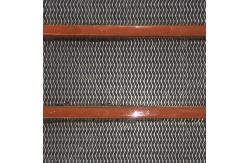

12.5mm Aperture Heavy Duty Resis Self-Clean Mesh Tension Screen

|

|

12.5mm Aperture Heavy Duty Resis Self-Clean Mesh Tension Screen

1,Self-Clean Mesh Tension ScreenSpecification:

① Progress Harp Type K This type of screens is made of round wavy, wires, curved in the horizontal working plain. Angle between the arms equals 90. Working size of W opening is created by diameter of the circle written into this opening. Wires placed one next to another create openings similar to a square. Working wires are buckled together with transversive wires using polyurethane, rubber or wires inside plastic cover. Opening sizes: 1.5 - 35 mm Ø Wire: 0.8 - 6.3 mm ② Progress Harp Type T They are produced with wires of round diameter – straight and wavy placed alternately on the horizontal working surface. Wave spread span equals 90 or 60 . Working size of W opening is created by the diameter of the circle written into this opening. Straight, round wires have a slightly larger diameter then wavy ones. This series of screens characterizes with high ability to withstand heavy loads (owing to very well stretched straight wires)and good self-cleaning effect, obtained by self – oscillation of wavy wires. Wires in this series of screens can be connected with each other using wire knots, polyurethane, rubber or transverse wires inside plastic cover. Opening sizes: 1.2 - 14 mm Ø Wire: 1 - 4 mm

2,Self-Clean Mesh Tension Screen Production Description:

3,Self-Clean Mesh Tension Screen Features:

High temperature resisting, acid resisting, alkali resisting, corrosion resisting.

4,Self-Clean Mesh Tension Screen Processing method:

Locked weave, Bi-directional plain weave, single wave weave, two-way wave weaving, rectangular opening weaving.

5,Self-Clean Mesh Tension Screen Uses:

Crimped mesh is widely used in mining, petroleum, chemical, construction, mechanical accessories, protective netting, packaging netting, barbecue netting, vibration screen, cooking utensils, can also be used for classification of solid materials screening, liquid and slurry filtration, aquaculture, civil and so on. 6,Self-Clean Mesh Tension Screen Details picture:

7,Our service:

① Strict quality control

From raw materials into the factory to the control of the process of production, to the finished product output.We have to pass strict inspection, each square meter to ensure that provide customers with perfect products.

② A lot of cash supply

A large number of spot supply, so that in the fastest time of delivery.

③ Security and meticulous packaging

There are three layers of protection: the first layer is a waterproof paper (if it is the high mesh products will add shock membrane to prevent breakage), the second layer is waterproof cloth, the third layer is a waterproof cloth packaging as a whole.Finally use wooden cases packaged as a whole.

④ Round-the-clock service

Welcome your consultation, can by phone, email, instant messaging tools to contact us;I'm very glad to answer questions for you.

|

| Product Tags: polyurethane screen mesh vibrating screen wire mesh |

|

Quarry Screen Mesh Polyurethane Fine Screen Mesh For Fine Particle Separations |

|

Non Metallic Raw Material Ore Magnetic Separator |

|

HT2036 High Precision Rectangular Gyratory Sifter For Quartz Sand Screening |

|

Microporous Alumina Ceramic Vacuum Plate For Mining Industry Dewatering |

|

6M2 Porous Ceramic Filter Plate For Mining Industry Dewatering |

|

12M2 Ceramic Filter Plate For Mineral Soild Liquid Separation |