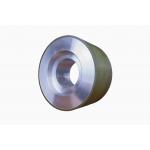

Sharp Cutting Vitrified Grinding Wheels, Excellent Surface Finish

|

Detailed Product Description

|

Vitrified Diamond Wheels For PCD/PCBN Cutting Tools The vitrified bond grinding wheel has the advantages of

high-temperature resistance, high machining efficiency, good

rigidity, good tool shape retention in the grinding process, and

high dimensional accuracy of finished products. Vitrified diamond

grinding wheel grind PCD, PCBN tools, which can greatly improve

grinding efficiency (It is 4 times of that of metal bond), and

grinding ratio is low, service life is long (It is about 150 times

longer than that of resin wheel.), At the same time, the grinding

surface quality of vitrified wheel is good, which is similar to

that of metal bond grinding wheel.

Feature:

Specification:

Application:

workpiece include PCD, CVD, PCBN, carbide, ceramic tools and other

cutting tools milling cutter, bit, reamer and other cutting tools

grinding and rapid high efficiency and low damage grinding. 6A2/12A2 for edge grinding inserts and solid cutting tools ued on

Ewag, Wendt and Farman Machines. 11A2/2A2/6A2 for peripheral grinding inserts used on Agathon,Wendt

and Waida machines. 3A1/14A1 for cylindrical grinding reamers and end milling tools

used for manual and CNC cylindrical grinder. |

|||||||||||||||||||||||||||||||||||||

| Product Tags: vitrified bond grinding wheel diamond cutting wheel |

Related Products

|

Grit D5-D151 Grinding Wheel For Cutting Tools Industry High Precision |

|

Hybrid Bond 1A1 1V1 Diamond Cbn Grinding Wheels 50-175 Mm |

|

1A1 1V1 Grinding Wheel For Cutting Tools Industry High Precision |

|

1A1 50-250 Grit Resin Bond Diamond Grinding Wheel For CNC Machine |

|

11V9 12V9 Hybrid Bond Grinding Wheel For Cutting Tools Industry 150 grit |

|

D46-D107 Grit Resin Bond Diamond Wheels High Cutting Effeciency |

Email to this supplier