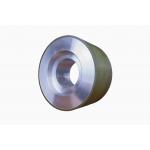

11V2 Grinding Wheel For Cutting Tools Industry

|

Detailed Product Description

|

Resin Bond Wheels For Tool & Cutter Resin bond wheels has free cutting, self-sharpening, good rigidity and strength,

less heat and jam generated in grinding, easy control of the

precision and easy dressing such characteristics.

Specification:

Feature:

Application:

Different from Hybrid bond's aggressive ability, Resin Bond

grinding wheel offers better surface quality and can be formed in

complex shapes. We provide phenolic and polyimide bond which is

widely usedd for tungsten carbide, HSS, ceramic and stellite

Cutters. Common grinding machines such as: ANCA, WALTER, VOLLMER,

ROLLOMATIC, SAACKE, DECKEL, HAWEMAT, WOTER, NAGOYA... 1, High wheel shape retention, suitable for the high precision

tools operation 2, High stock removal 4-7mm 3, Superior surface quality 4, Very low spindle load 5, Fast cutting speed 6, High wear resistance for longer life For any inquire, quality feedback or technical question, there

always be a professional responding answered by our technician team

within 24 hours. |

|||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 11V2 vitrified bond grinding wheel 11V2 Grinding Wheel For Cutting Tools Industry D151 Grinding Wheel For Cutting Tools Industry |

Related Products

|

Grit D5-D151 Grinding Wheel For Cutting Tools Industry High Precision |

|

Hybrid Bond 1A1 1V1 Diamond Cbn Grinding Wheels 50-175 Mm |

|

1A1 1V1 Grinding Wheel For Cutting Tools Industry High Precision |

|

1A1 50-250 Grit Resin Bond Diamond Grinding Wheel For CNC Machine |

|

11V9 12V9 Hybrid Bond Grinding Wheel For Cutting Tools Industry 150 grit |

|

D46-D107 Grit Resin Bond Diamond Wheels High Cutting Effeciency |

Email to this supplier