Lead Free SS316L SMT Soldering Machine For Assembly Line RF 400A

|

|

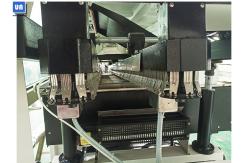

Lead Free SS316L SMT Soldering Machine For Assembly Line RF 400A

SMT Lead Free Wave Soldering Machine for Assembly Line RF-400A

Product Performance of wave solder RF-400A

Specifications of wave solder RF-400A

Information about wave solder RF-400A Solder types

Effects of cooling rate

Installation Drawing Detailed Picture of wave solder RF-400A |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: SS316L SMT Soldering Machine RF 400A SMT Soldering Machine SS316L SMT Assembly Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lead Free SMT Machine PCB Wave Soldering Machine RF-350A For Assembly Line |

|

PCB Lead Free Wave Soldering Machine For SMT Production Line RF-350B |

|

PC PLC Control Lead Free Wave Soldering Machine For SMT Assembly Line |

|

Lead Free SMT Production Line Wave Soldering Machine With 3 Preheating Zones |

|

Lead Free PCB Wave Soldering Machine For DIP Production Line |

|

1800mm Zone Wave Soldering Machine RF-350XL Lead Free Step Motor Control PLC |