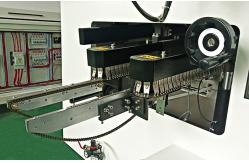

Wave Soldering Machine

RF-350A Lead Free Wave Solder

Specifications

| Spraying System |

| Transmission Method | Air cylinder |

| Spraying Pressure | 0.25MPa ~ 0.4MPa |

| Flux Flow | Flux Flow meter |

| Auto Flux Feeding | Optional |

| Exhaust Method | Upper Exhaust |

| Exhaust Capacity | 25M3/min |

| Preheating System |

| Preheating Model | IR tube Option : Hot Air Convection |

| No. of Preheating Zones | 3 |

| Preheating Length | 1800 MM |

| Preheating Temp. | Room Temperature : ~300C |

| Warm Time | Approx. 20/min |

| Conveyor System |

| PCB Width ( L x W ) | 350 MM |

| Conveyor Direction | Optional |

| Conveyor Height | 750 MM |

| Componet Clearance (mm ) | 130 MM |

| Conveyor Width Adjustment | Manual |

| Conveyor Angle | 4 ~ 6 C |

Features

1. Totally design for Lead Free process.

2. Streamline design design with the curve glass windows for easy

viewing and maintenance.

3. PLC control and temperature control meter.

4. Standard adopted high quality cylinder and nozzle to get uniform

flux spraying,

adding the curtains to reduce the leakage of flux

smog.

5. The preheating zones using the high efficiency IR ceramic

heaters (option : Hot air convection )

to achieve strong and stable heating results.

6. Special alloy transportation chain claws, non-stick tin and

ensures the quality of welding PCB board.

7. Tin stove adopts imported high frequency conversion motor

independent control, stable performance.

8. Tin stove preheating furnace uses high-speed PID and 2

independent infrared heating (IR heating) control.

9. Time can be controlled, we can preset switch functions, tin

stove can heat within 90 minutes.

10. With black box memory function, the machine can always store

the production management records,

improve work efficiency.

11. Automatic claw cleaning function ensure the cleanliness

of claws.

12. Reasonable design and sensitive fault security alarm system

ensure the stable

performance and operators' safety.

13. Lead-free solder furnace with independent design, environmental

protection and safety, easy to clean.