Double Acting Hollow Chuck , Pneumatic Four Jaw Lathe Chuck

|

|

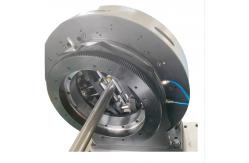

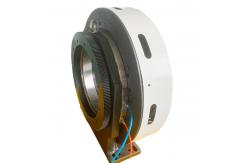

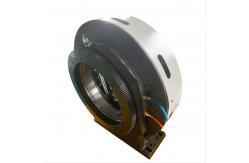

M170J Four-Jaw Simple Pneumatic Double-acting chuck for laser cutting machine

Feature:

1. The fixture quickly improves work efficiency:

Automatic. Compared with manual chucks, laser chucks can automatically rest assured by just clicking a button, the force is stable and reliable, and the size can also be adjusted. Customers can choose soft nails, hard nails, and customized special-shaped nails that match the chuck. The size of the workpiece can be adjusted to the position of the chuck. In addition to improving work efficiency, one person can also operate multiple CNC machine tools, greatly reducing human resource costs and reducing investment in fixed equipment. It is widely used in batch, single-product machining enterprises.

2. Reduce labor and improve corporate image:

The use of laser chucks, while improving production efficiency, can not only greatly reduce the labor intensity of laborers, but also make your company a model of considerate laborers, adding new opportunities for the recruitment of corporate personnel and product market competitiveness. Highlights, improve the level of equipment, and improve the overall image of the company.

3. Strong safety and reliability:

The laser chuck is used in the performance test authorized by the country. All the accessories measured meet the national standard. In the 3MPa water pressure test, all the components are not damaged. It is mainly converted by the wedge angle and pressure. In addition to blessing it has a strong self Lock function, and firmly clamp the workpiece for cutting when the power is disconnected, which solves the safety and reliability problems of domestic customers.

Technical features:

1. Large through hole pneumatic pressure maintaining type four-claw double;

2. Adopt the advanced alloy steel material, all with the surface by surface

hardening treatment, in order to improve the accuracy and durability;

3. Matching surfaces of all parts hardened, ground and lubricated directly;

4. Can clamp the round tubes, square tubes, rectangular tubes, oval tubes and all kinds profiles with different shapes;

5. Suitable for clamping part of a workpiece inserted into the through hole, checking

the seating, or modifying spindle coolant specifications;

6. Low noise, large stroke.

WORK SHOP:

FAQ: Q:What's the OEM serivce of OREE LASER? A1:1. Customized and OEM orders are welcome if you need; 2. All the OEM services are free, customer only need to provide us with your logo drawing, function requirements, colors etc; 3. No MOQ required. Q: Will the package damaged during transportation? A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe tranportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition. Q: How can I do if the machine goes wrong? A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you. Plenty of technical support online is available; free global regional training services. Q: What's your MOQ? A: We don't have MOQ. No matter 1set order or 100sets order, we will give you support with our heart and soul. Q: What's the QC system or OREE LASER? A1. Skilled and strict Quality Inspection Team is available during the material purchasing and production procedure; 2. Random sample testing by Quality Control; 3. Traceability for OREELASER machines; 4. Certified according to ISO 9001

WHY CHOOSE LINGMAN: A: Professional Factory: We have 20year special experience in manufacturing& exporting

gears.Our imporoved and advanced enquipment and owned skilled

B:Good material and Quality:

Since we are honest factory,we expect and look forward long

cooperation,So material and quality we paid high attention. And for

C.Technicial support:

We can revise size as your request to meet your machine.

D.Best services: We do best effort we can to our customers.

|

||||||||||||

| Product Tags: Double Acting Hollow Chuck Stainless Steel Hollow Chuck Pneumatic four jaw lathe chuck |

|

Universal High Quality 3-jaw Hollow Chuck Hydraulic Power Chuck for CNC Lathe |

|

High Clamping Accuracy 3 Jaw Hollow Hydraulic Lathe Power Chuck |

|

3 Jaws Hollow Structure CNC Machine Power Hydraulic Lathe Chuck |

|

Hollow Type 3 Jaws Chuck Hydraulic Power Chuck for Pipe Cutting Machine |

|

3-jaw Hollow Chuck Hydraulic Power Chuck for Pipe Cutting Machine |

|

Through Hole 3 Jaws CNC Machine Power Hydraulic Lathe Chuck |