2190kg Positioning Machine For Gluing Rigid Box L5981xW3182xH2103mm

|

|

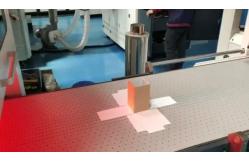

Positioning Machine For Gluing Rigid Box Paper And Paste Box With Paper Together

Nowadays, the visual positioning machine has been applied in the production of rigid box, gift box, shoe box, cellphone box, cosmetic box, ring box, book cover, case, hard cover etc.

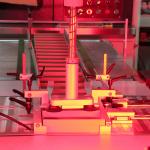

Gluing system of positioning machine introduction:

When the paper is glued, the drum must be turned on and then the glue is drawn. The glue will flow out from the glue outlet above the drum. First adjust the "paper roller" and the paper feed roller in sequence according to the thickness of the paper. Then adjust the position of the scraper according to the size of the paper. Generally, the scraper is at least one in the middle of the paper and one on each side. If the number of scrapers is too small, the paper may not be completely scraped off.

Main features:1. High speed, Max speed is 42 pcs/min. 2. Easy handle and operate, the The fastest set-up time of

change model is 7 minutes. 3. No-move camera when change sizes. 4. Double Germany Basler cameras (ten million pixels). 5. Dual feeding system, no need to installation again when change

box to hardcover model. 7. Panasonic Servo motor feeding system. Advantages:

Can connect with four sides wrapping machine to make the hardcover Can work with box wrapping machine to make rigid box Can make special box, such as slant side box (videos are

available) Can be upgraded to a fully automatic box making machine in the

future if needed.

With two our semi-automatic rigid box wrapping machine, the

speed of machine can make around 14000 pcs per day

Only need 7 minutes when change product mode One bottom to change case to box No stop working when change different size, because one F6 for

presetting and another one can keep working Optional function:

Specifications of LS-450plus:

We are one of the leading & professional manufacturer of Grooving machines and Fully Automatic/Semi-automatic Rigid Box Making Machine in Dongguan, China Since 2006.

We have independent R&D department. Up to now, We have got more

than 20 patents including pratice patents, appearance patents and

technology-based patents. We have been specialized in post-press

machinery's research, development, manufacturing and selling for

more than 15 years. Grooving machine series and rigid box forming

series are our main products. We hold "professional, focus, customer first" as our operating principle, insist on surviving from good quality, improving efficiency from prescise management, developing from creativity. We are committed to spare no effort to become the national brand and contribute our strength in Printing&Packaging industry.

Our service:

Pre-sale service: * Inquiry and consulting support. * Order confirmation

After-sale service: * Machine installation and training in customer factory. |

||||||||||||||||||||||||||||||

| Product Tags: Positioning Machine For Gluing Rigid Box 2190kg Positioning Machine L5981mm Rigid Box machine |

|

automatic LS-450 Plus no-move camera gift computer ring rigid box positioning machine |

|

Semi Automatic Glue Application System For Rigid Box Hard Cover Making Line |

|

Semi Automatic Glue Application System For Rigid Box Manufacturing |

|

Semi-Automatic Box Gluing Equipment For Book Cover CD Boxes Making Line |

|

Semi-Automatic Box Gluing Equipment For Hard Cover Boxes line |

|

Semi-Automatic Box Gluing Equipment For Hard Cover Boxes |