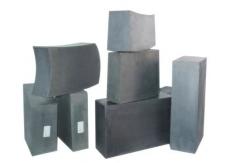

Magnesia Carbon Bricks Magnesia Carbon Bricks It Improves The Corrosion Resistance And

Slag Resistance With Its Added Graphite. Magnesia Carbon Bricks - We proudly represent the largest

manufacturer of Magnesia Carbon brick in China, with top quality

Magnesite-Carbon bricks gaining fame world-wide. Magnesite-Carbon

brick is non-fired basic refractory material. It improves the

corrosion resistance and slag resistance with its added graphite.

There are three main types of Magnesite-Carbon brick to choose

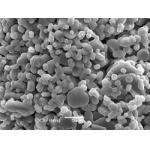

from: Magnesia Carbon BrickMaterial and Technique: Magnesia-Carbon brick is resin-bonded brick

made from dead-burned or fused magnesia and graphite. Anti-oxidant

is added if required. Properties: Magnesia-Carbon brick has good performance in thermal

resistance, corrosion resistance, and spalling resistance. Application: widely used in converters, EAFs, ladles, and refining

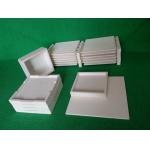

furnaces Other Carbon-Containing refractory material Alumina-Magnesia-Carbon Brick and Magnesia-Alumina Carbon BrickMaterial and Technique: made from high quality Bauxite, corundum,

fused magnesia, and graphite Properties: Alumina-Magnesia-Carbon brick has appropriate residual

expansion, low thermal conductivity, and better insulation

performance than that of Magnesia-Alumina Carbon brick.

Magnesia-Alumina Carbon brick has the performance between that of

Magnesia-Carbon and Alumina-Magnesia-Carbon. Application: used in the slag line of the ladle, lower part of the

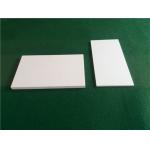

ladle wall, ladle bottom, and free zone of the ladle Magnesia-Calcium-Carbon BrickMaterial and Technique: made from high quality magnesia, dolomite

clinker, and synthetic magnesia-dolomite clinker Properties: good slag resistance, stability in high-temperature

vacuum working environment, and can purify liquid steel - Application: mainly used in refining furnaces such as VOD, AOD, and

LF

|