CERAMIC FOUNDRY SAND

|

|

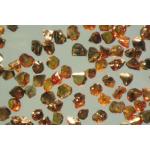

Ceramic Foundry Sand This new developed specific Foundry Sand is produced from the

special selected high quality refractory raw material at very high

temperature at 2,300 – 2,500℃. Our these ACFS sand has excellent

solid cores with high strength and very low resin addition rates.

The materials has excellent crystalline with formula is

5Al2O3-SiO2. Application: Shell moulds and cores for casting gray, Malleable and nodular cast

iron, alloyed steel and carbon steel, non-ferrous metals, etc. The Main Advantage * Stabe quality on the chemical composition * Perfect grain round shape and various grain sizes * High gas permeability * High temperature resistance * Good break down and fast curing and good release

Chemical Composition

Physical Character

Size Distribution (Typical)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 2.1g/Cm3 Density Ceramic Foundry Sand Round Ball Shape Ceramic Foundry Sand Round Ball Shape Alumina Ceramic Parts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||