SS316L Twill Weave Wire Mesh Cloth 500Mesh 0.001" Wire 25um Opening

|

SS316L Twilled Weave Wire Cloth 500Mesh 0.001" Wire 25um Opening

Stainless Steel Twill Weave Square Wire Cloth Introduction:

Twill Weave Mesh is fabricated by passing every shute wire alternately up and down of two warp wires. The pattern is staggered on following warp wires, providing a parallel diagonal lines appearance. Twill Weave Wire Mesh permits the use of relatively heavier wires in the specific mesh count than is feasible in the plain weave mesh. This mesh has broad application tendency of supporting larger loads and finer filtrations.

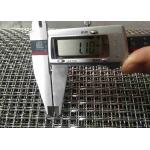

500 mesh twill weave stainless steel wire mesh including 500 wires and openings per inch. Using 0.001" diameter wire, by twill weaving, woven 500 mesh opening for 0.025mm liquid or gas filter. This wire diameter and mesh with ratio reasonable, therefore weave structure is very strong. After 13 whole weaving process, so that the mesh surface flatness better.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Twill Weave Wire Mesh | |||||

| Mesh | Mesh Opening | Wire Diameter | Open Area | ||

| Inch | MM | Inch | MM | (%) | |

| 4 | 0.215 | 5.460 | 0.0350 | 0.890 | 74.00% |

| 8 | 0.105 | 2.667 | 0.0200 | 0.508 | 70.60% |

| 12 | 0.065 | 1.651 | 0.0180 | 0.457 | 60.80% |

| 14 | 0.062 | 1.585 | 0.0090 | 0.228 | 76.40% |

| 35 | 0.017 | 0.422 | 0.0120 | 0.305 | 33.60% |

| 40 | 0.017 | 0.419 | 0.0085 | 0.216 | 43.60% |

| 45 | 0.013 | 0.324 | 0.0095 | 0.241 | 32.80% |

| 58 | 0.013 | 0.324 | 0.0045 | 0.114 | 54.60% |

| 66 | 0.011 | 0.269 | 0.0045 | 0.114 | 49.40% |

| 70 | 0.008 | 0.198 | 0.0065 | 0.165 | 29.70% |

| 90 | 0.006 | 0.155 | 0.0050 | 0.127 | 30.30% |

| 100 | 0.006 | 0.140 | 0.0045 | 0.114 | 30.30% |

| 100 | 0.005 | 0.127 | 0.0050 | 0.127 | 25.00% |

| 110 | 0.005 | 0.117 | 0.0045 | 0.114 | 25.50% |

| 120 | 0.004 | 0.109 | 0.0040 | 0.102 | 26.80% |

| 130 | 0.004 | 0.109 | 0.0034 | 0.086 | 31.10% |

| 130 | 0.004 | 0.099 | 0.0038 | 0.097 | 25.60% |

| 140 | 0.004 | 0.097 | 0.0033 | 0.084 | 28.60% |

| 160 | 0.004 | 0.097 | 0.0024 | 0.061 | 37.90% |

| 180 | 0.004 | 0.095 | 0.0018 | 0.045 | 45.70% |

| 170 | 0.004 | 0.089 | 0.0024 | 0.061 | 35.10% |

| 180 | 0.003 | 0.086 | 0.0023 | 0.058 | 34.70% |

| 180 | 0.003 | 0.079 | 0.0025 | 0.063 | 30.60% |

| 200 | 0.003 | 0.074 | 0.0021 | 0.053 | 33.60% |

| 200 | 0.003 | 0.069 | 0.0023 | 0.058 | 29.20% |

| 270 | 0.002 | 0.053 | 0.0016 | 0.040 | 32.20% |

| 325 | 0.002 | 0.043 | 0.0014 | 0.036 | 29.70% |

| 400 | 0.033 | 0.0013 | 0.030 | 0.0011 | 27.83% |

| 500 | 0.025 | 0.0010 | 0.025 | 0.0009 | 25.79% |

| 600 | 0.024 | 0.0009 | 0.018 | 0.0007 | 33.03% |

| 635 | 0.025 | 0.0009 | 0.015 | 0.0005 | 39.06% |

Weaving Type: Twill Weave

Twilled weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of a yarn that crosses over two or more yarns from the opposite direction.

Features:

Durability with good abrasion resistance.

Smooth surface.

Square mesh.

Good chemical resistance, especially against solvents.

Excellent mechanical strength.

Easy to cut to size with wire cutters, tin snips or metal shears.

Applications:

Filters and Laboratories

Electronic Ciggaretts for Wicking Material

Seiving and Straining of the Fines Powders

Injection Powders

Dusts Selection

Screening Chemical Additives

Oil Fine Filter

Gas Flow Control

Packing:

|

Square Stainless Welded Wire Mesh Plain Weave Type And Twill Weave Type |

|

Versatile Steel Woven Mesh Commonly Used Material In Various Industries |

|

Stainless Steel 904L Woven Wire Mesh Superior Corrosion Resistance |

|

40 Mesh Counts Woven Wire Mesh Stainless Steel 304 Bulk Produce In Stock |

|

Square Hole SS Woven Wire Mesh 18x18 Mesh Selvage Edge |

|

Waterproof Paper Packaging SS Woven Wire Mesh Twill Weave Edge |