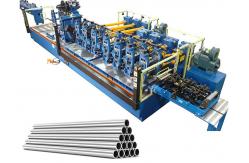

GI Steel Square Tube Machine is a series of machines that builds

longitudinal weld seam tubes and pipes with steel strips of certain

width.

- It starts by uncoil and flatten the slitted steel coils into steel

strips.

- The flattened steel strips will then be inserted into the forming

machine and the roller tolling in the machine will roll the strip

to round pipe shape.

- The rolled strips will then be sent into the weld box where the

tube is welded by a high frequency solid state welder.

- The welded tubes will be formed to expected shape or size in a

sizing machine. Finally the tubes will be cut to length and

bundled.

Why Choose us?

- Focus on motion control for 25+ years, customize

equipment,Independent research and development, production and

sales, no middlemen make a difference

- Many years export experience, serves hundreds clients in 60

countries

- Top engineer team, advanced production process, maximize returns

for client

- 24 hours online service, excellent service system

- Smart factory full-line solution integration, providing

high-quality control solutions, saving customers a lot of time and

costs.

Advantages

√ High production efficiency, line speed can be up to 50m/min.

√ High yielding, the machine works stably at a high speed, which

improves the yielding of products.

√ Low wastage, low unit wastage and low production cost.

√ High accuracy, diameter error is only 0.5/100 of the pipe OD

Technical Flow Of The Production Line

Parameter list

| Model | Round pipe(mm) | Square pipe(mm) | Thickness(mm) |

|

| SP20 | Ф8-Ф20 | 6x6-15x15 | 0.3-1.5 |

| SP32 | Ф10-Ф32 | 10x10-25x25 | 0.5-2.0 |

| SP50 | Ф20-Ф50 | 15x15-40x40 | 0.8-3.0 |

| SP76 | Ф32-Ф76 | 25x25-60x60 | 1.2-4.0 |

| SP89 | Ф42-Ф89 | 35x35-70x70 | 1.5-4.5 |

| SP114 | Ф48-Ф114 | 40x40-90x90 | 1.5-4.5 |

| SP140 | Ф60-Ф140 | 50x50-110x110 | 2.0-5.0 |

| SP165 | Ф76-Ф165 | 60x60-130x130 | 2.0-6.0 |

| SP219 | Ф89-Ф219 | 70x70-170x170 | 2.0-8.0 |

| SP273 | Ф114-Ф273 | 90x90-210x210 | 3.0-10.0 |

| SP325 | Ф140-Ф325 | 110x110-250x250 | 4.0-12.7 |

| SP377 | Ф165-Ф377 | 130x130-280x280 | 4.0-14.0 |

| SP406 | Ф219-Ф406 | 170x170-330x330 | 6.0-16.0 |

| SP508 | Ф273-Ф508 | 210x210-400x400 | 6.0-18.0 |

| SP660 | Ф325-Ф660 | 250x250-500x500 | 6.0-20.0 |

| SP720 | Ф355-Ф720 | 300x300-600x600 | 6.0-22.0 |

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for centering jumpiness.

(3)Every roller will be checked to make sure it's in the range of

tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you? what are the differences between you

and other Chinese suppliers?

A: We are concentrating on pipe-making machines for more than 20

years. We have constructed many steady trading partners in Asia,

Africa, the middle east, Europe, and South America throughout the

years. Our innovative designed production line and every single

unit of the production line are economical and practical.