10 way dual speed industrial remote control with button text identification: UP, DOWN, EAST, West, SOUTH,

NORTH, 1, 2, 3, 4, START, STOP, power indicator light, signal

indicator light;

Main function: Control the operation of equipment up, down, east, west, north,

south, 1, 2, 3, and 4. The normal mode is jog mode, with up and

down interlocking, east-west interlocking, north-south

interlocking, 1 and 2 jog and interlocking, 3 and 4 jog and

interlocking, 5 and 6 jog and interlocking. Each action can achieve

fast and slow control, with conventional pressing to execute slow,

and quick double clicking to change to dual speed.

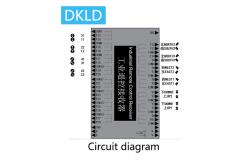

12 dual speed buttons, each corresponding to 2 normally open relay

outputs at the receiver end. The upper and lower, east and west,

south and north, 1 and 2, 3 and 4, and 2 speed relays can be

designed as shared.

Product highlight: Good anti-interference performance, with unique identification

codes between each remote control transmitter and receiver,

reaching hundreds of millions of sets, never repeating, and

strictly avoiding mutual interference and potential interference.

And the remote control has up to 50-256 frequency points, and each

set in the same environment can be configured with separate

frequency points. Even if the frequency points overlap, given the

uniqueness of the ID identification code, there will be no impact

on each other, ensuring safety and reliability.

Usage: crane, overhead crane, crane, electric hoist, gantry crane,

cantilever crane, portal crane, port crane, wharf crane, ship

crane, bridge erecting machine, beam lifter, etc. within the

4-point switching value, as well as elevators, hoists, lifting

platforms, winch, motors, plate shears, sand screeners, concrete

pumps, electric flat cars, industrial furnace doors, winch winches,

etc.

Technical parameters: remote control distance of 100 meters, 250 meters, working

temperature of -35 ° -+75 °, transmitter power supply of 3 No. 5

dry batteries of 4.5V, receiver terminal conventional working

voltage of 12-24V AC/DC, other voltages of AC220V or AC380V, etc.,

can be adapted through external transformer voltage conversion.

Model and configuration instructions: This machine model comes standard with 1 transmitter and 1

receiver. The transmitter antenna is built-in, and the receiver is

equipped with an external extended suction cup antenna (1 meter

long feeder), which is attached to the outside of the distribution

box and installed inside the receiver.