Length 2000mm Welded Steel Grating Serrated Galvanised Grid Mesh

|

Detailed Product Description

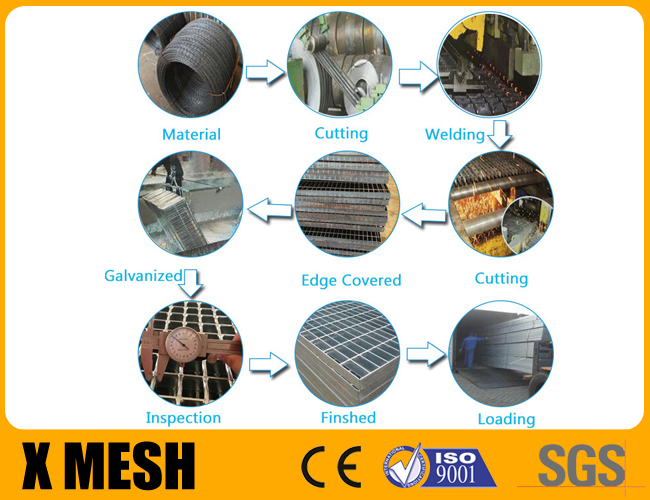

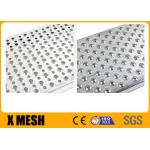

Galvanized finish Serrated Surface 2000mm Length Welded Steel GratingWelded Steel Grating Introduction:Stainless Steel GratingSteel Bar Grating with bearing bars thicker than 3/16" is considered to be "Heavy Duty" and carries the designation prefix "Type HD". Available bar thicknesses are 1/4" (6.4mm) , 5/16" (7.9mm) and 3/8" (9.5mm) in either plain or serrated surface. Standard depths range from 1" (25mm) up to 4" (102mm), although larger sizes are available upon request.Tru-Weld Heavy Duty Steel Bar Grating is commonly used for floor trenches and sump covers exposed to heavy equipment traffic. It is used extensively through out mining, power generation, highways, airfields, and on truck terminal loading docks and ramps. It is suitable for large single span conditions or where grating must be support extreme loads.*All weights will increase by 5% when galvanized.Tru-Weld bar grating is forge-welded, a system in which Qijie Grating was a pioneer. In this process the bearing bars and cross rods are permanently forged together by heat and pressure into a single unit construction, resulting in greater strength per pound than mechanical assembly methods. The twisted cross rods provide a non-slip walking surface. For applications where extremely slippery conditions prevail, Serrated bar grating offers a superior grip surface to the load bearing bars.Bar grating types are specified by bearing bar spacing followed by cross rod spacing. In imperial measurements, bearing bar spacing is described in sixteenths of an inch. Therefore, Type 19 has bearing bar centers at 19/16 of an inch (or 1 3/16”). Type 15 has bearing bar centers at 15/16”. Type 11 is at 11/16” etc. The second number after the dash in the Type designation refers to the cross rod spacing. Cross rods are available in either 4” (standard) or 2” (special) spacings.All bar grating Types may also be described in metric units. Again, the first number represents the bearing bar spacing on centers and the second number represents the cross rod spacing, both units measured in millimeters. Therefore, Type 30-102 Metric equals bearing bars at 30mm centers and cross rods at 102mm centers. This is the metric equivalent of Type 19-4.Note: Although the special 2” (50mm) cross rod spacing does allow for less open space on the grating surface, it does not affect the load rating of the grating. The most economical and readily available choice for bar grating selection is Type 19-4 (Type 30-102 Metric).Quality Standard Qindelin follows in production:Steel Grating Standard: China YB/T4001-1998America ANSI/NAAMM (MBG531-88)Britain BS4592-1987Australia AS1657-1992Steel Standard: China GB700-88 / ASTM (A36) / BS4306 (43A)Hot Dip Galvanizing Standard: China GB/T13912-92 / ASTM (A123) / BS729Welded Steel Grating Specification:

====TU Type Bar Grating:FOR SIDEWALK LOADING

Aluminum Grating

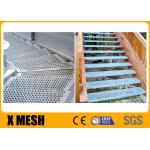

Welded Steel Grating Applications:Uses: Stainless steel bar grating is mainly used in chemical industry, food processing, hydro processing and other industries as listed:Power plant;Chemical plant;Oil Refinery;Steel plant;Machinery plant;Paper-making factory;Cement plant;Civil engineering;Wastewater treatment;Pharmacy industry;Food processing.Welded Steel Grating Feature:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Length 2000mm Welded Steel Grating Length 2000mm galvanised grid mesh Serrated galvanised grid mesh | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

Bs729 Standard Machinery Plant Galvanized Steel Grating Cross Bar 5mm |

|

Astm A121 Standard Plain Steel Grating Pharmacy Industry Using Cross Bar Pitch 100mm |

|

3mm Stainless Galvanized Welded Steel Grating High Strength Good Bearing Capacity |

|

Aluminum And Mild Carbon Punched Galvanised Walkway Grating Welded |

|

5 Diamonds Walkway Channel Perforate Metal Welded Steel Grating Antirust |

|

Hot Dipped Galvanised Grip Strut Perforated Metal Mesh Plank Grating Silver Welded |

Email to this supplier