Food processing Width 1000mm Stainless Steel press - locked grating press - locked grating Introduction: Stainless Steel GratingStainless steel bar grating is a choice for corrosive environments

such as chemical, food and hydro processing areas. It is available

in welded and press locked as well as in many bearing bar sizes. Materials: The most common material is Type 304 (SUS304), however,

Type 316 (SUS316) or Type 316L (SUS316L) is also available. 304

stainless steel is the most popular type contains both chromium and

nickel to provide excellent balance resistance and workability. 316

stainless steel is better corrosion, pitting resistance and higher

strength at elevated temperatures than 304. 316L is extra low

carbon variation of 316 to avoid carbide precipitation due to

welding. Aluminum Gratingaluminum grating is designed to be a high-strength, low-weight

product that uses an I-bar or rectangular bearing bar with cross

rods hydraulically swaged under high pressure. Thus, giving you a

rigid, virtually maintenance-free flooring product. Similar to steel grating, aluminum grating can be pressure locked

as an alternative to swage locked. This application process also

allows the customer to choose a close mesh grate where certain

special needs are to be met. Open Mesh GratingThe open mesh steel grating is a flat panel with a light structure

firmly welded together. It is widely used for industrial ladders,

decking safety, ventilation ceilings and floors, platform and stair

tread protection panels. The open spacing design instead of solid

metals allows good ventilation, and easy flow of lighting and heat.

The standard sheet size is 1m x 6m standard type (special size and

American standard size are also customizable). Mostly Used Specifications of Steel Mesh Gratings from our

customers:1) Bearing Bar (Load Bar) Specifications (mm): The specification of

plain type and serrated type bearing bar is 20 x 3 to 100 x 10; The

specification of I-section type is 25 x 5 x 3, 32 x 5 x 3, 38 x 5 x

3, 40 x 5 x 3, 50 x 5 x 3, 50 x 7 x 4, 55 x 7 x 4, 60 x 7 x 4, 65 x

7 x 4 , 70 x 7 x 4, 75 x 7 x 4, etc. 2) Bearing Bar Pitch (center to center): 12.5, 15, 25, 30, 30.16,

32.5, 34, 40, 41.25, 45, 50, 60, 60.32, 80, 100 mm etc, also be

according to client's requirement and 30, 40, 60mm are recommended,

America standard is available. 3) Material: Mild Steel (Low Carbon Steel) or Stainless Steel 4) Surface Treatment: Mill finish untreated, Painting or Hot DIP

Galvanizing Mesh gratings are popular due to the following features: 1. High strength and light structure2. Powerful anti-corrosion, durable and long working life3. Beautiful appearance, bright surface4. No dirt-rain-snow deposit, automatic cleaning, easy maintenance5. Good ventilation, day-lighting, heat-dispersing, resistant to

sliding and explosion.6. Easy installation and disassembly Quality Standard Qindelin follows in production:Steel Grating Standard: China YB/T4001-1998America ANSI/NAAMM (MBG531-88)Britain BS4592-1987Australia AS1657-1992Steel Standard: China GB700-88 / ASTM (A36) / BS4306 (43A)Hot Dip Galvanizing Standard: China GB/T13912-92 / ASTM (A123) /

BS729 press - locked grating Specification:

A

| Type | Grating | Frame | Load Bar Pitdn | | | Width | B | C | D | E | Angle | | 200 | TGD-A200-25 | 1002 | 300 | 25 | 315 | 30 | L30X30X3 | 20 | 250 | TGD-A250-25 | 1002 | 350 | 25 | 365 | 30 | L30X30X3 | 20 | 300 | TGD-A300-25 | 1002 | 400 | 25 | 415 | 30 | L30X30X3 | 20 | 350 | TGD-A350-25 | 1002 | 450 | 25 | 465 | 30 | L30X30X3 | 20 | 400 | TGD-A400-25 | 1002 | 500 | 25 | 515 | 30 | L30X30X3 | 20 | 450 | TGD-A400-25 | 1002 | 550 | 25 | 565 | 30 | L30X30X3 | 20 | | 200 | TGD-B200-25 | 992 | 300 | 25 | 315 | 30 | L30X30X3 | 15 | 250 | TGD-B250-25 | 992 | 350 | 25 | 365 | 30 | L30X30X3 | 15 | 300 | TGD-B300-25 | 992 | 400 | 25 | 415 | 30 | L30X30X3 | 15 | 350 | TGD-B350-25 | 992 | 450 | 25 | 465 | 30 | L30X30X3 | 15 | 400 | TGD-B400-25 | 992 | 500 | 25 | 515 | 30 | L30X30X3 | 15 | 450 | TGD-B450-25 | 992 | 550 | 25 | 565 | 30 | L30X30X3 | 15 |

Class | A | Type | Grating | Frame | | | | Width | B | C | D | E | Angle | | 200 | TG200-20 | 995 | 300 | 20 | 320 | 25 | L50X25X5 | | 250 | TG250-20 | 995 | 350 | 20 | 370 | 25 | L50X25X5 | | 300 | TG300-25 | 995 | 400 | 25 | 420 | 30 | L50X30X5 | | 350 | TG350-25 | 995 | 450 | 25 | 470 | 30 | L50X30X5 | | 400 | TG400-25 | 995 | 500 | 25 | 520 | 30 | L50X30X5 | | 450 | TG450-25 | 995 | 550 | 25 | 570 | 30 | L50X30X5 | | 500 | TG500-25 | 995 | 600 | 25 | 620 | 30 | L50X30X5 | | 550 | TG550-25 | 995 | 650 | 25 | 670 | 30 | L50X30X5 | | 200 | LHTG200-25 | 995 | 300 | 25 | 320 | 30 | L50X30X5 | | 250 | LHTG250-25 | 995 | 350 | 25 | 370 | 30 | L50X30X5 | | 300 | LHTG300-32 | 995 | 400 | 32 | 420 | 37 | L50X37X5 | | 350 | LHTG350-32 | 995 | 450 | 32 | 470 | 37 | L50X30X5 | | 400 | LHTG400-40 | 995 | 500 | 40 | 520 | 45 | L50X45X5 | | 450 | LHTG450-40 | 995 | 550 | 40 | 570 | 45 | L50X45X5 | | 500 | LHTG500-45 | 995 | 600 | 45 | 620 | 50 | L50X50X5 | | 550 | LHTG550-45 | 995 | 650 | 45 | 670 | 50 | L50X50X5 | | 200 | HTG200-32 | 995 | 300 | 32 | 320 | 37 | L50X37X5 | | 250 | HTG250-40 | 995 | 350 | 40 | 370 | 45 | L50X45X5 | | 300 | HTG300-45 | 995 | 400 | 45 | 420 | 50 | L50X50X5 | | 350 | HTG350-45 | 995 | 450 | 45 | 470 | 50 | L50X50X5 | | 400 | HTG400-50 | 995 | 510 | 50 | 530 | 55 | L55X55X5 | | 450 | HTG450-50 | 995 | 560 | 50 | 580 | 55 | L55X55X5 | | 500 | HTG500-60 | 995 | 630 | 60 | 650 | 65 | L65X65X5 | | 550 | HTG550-60 | 995 | 680 | 60 | 700 | 65 | L65X65X5 | | 200 | HHTG200-40 | 995 | 300 | 40 | 320 | 45 | L50X45X5 | | 250 | HHTG250-45 | 995 | 350 | 45 | 370 | 50 | L50X50X5 | | 300 | HHTG300-50 | 995 | 410 | 50 | 430 | 55 | L55X55X5 | | 350 | HHTG350-50 | 995 | 460 | 50 | 480 | 55 | L55X55X5 | | 400 | HHTG400-60 | 995 | 530 | 60 | 550 | 65 | L65X65X5 | | 450 | HHTG450-65 | 995 | 590 | 65 | 610 | 70 | L70X70X5 | | 500 | HHTG500-65 | 995 | 640 | 65 | 660 | 70 | L70X70X5 | | 550 | HHTG550-75 | 995 | 710 | 75 | 730 | 80 | L80X80X5 |

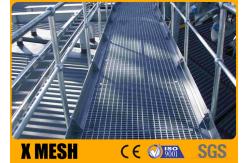

press - locked grating Applications: Power plant;Chemical plant;Oil Refinery;Steel plant;Machinery plant;Paper-making factory;Cement plant;Civil engineering;Wastewater treatment;Pharmacy industry;Food processing. press - locked grating Feature: Specifications: 19W4, Carbon Steel, Painted BlackApplications: Walkways, flooring, ramps, bridge flooring, trench

and drainage covers, mezzanines, platforms, stair treads, etc.Workability: Easy to Weld, Cut, Form and MachineMechanical Properties: Tensile = 58,000 +/-, Yield = 42,000 +/-How is it Measured? bar thickness X bar height, Bearing bars run

parallel to each other, the length of the panel.

The products enjoy the features of high strength, light structure,

high bearing, convenience for loading and other properties. |