Beryllium Copper Alloy C17200 25 Used For Electrical Industry

|

|

Beryllium Copper (BeCu) Alloy C17200 Alloy 25 Used For Electrical Industry Product Normal Description:

Introduction of Beryllium Copper (BeCu) Alloy C17200 Alloy 25: C17200, also known as Alloy 25, the most commonly utilized beryllium copper (BeCu) alloy and is notable for exhibiting the highest strength and hardness compared to commercial copper alloys. 172 copper strength and hardness are similar to that of steel. C17200 copper's ultimate tensile and Rockwell hardness properties in a peak aged condition are in the 200 ksi range and RC 45 respectively (electrical conductivity 22% IACS minimum).

172 BeCu copper is a high strength beryllium copper mold alloy. It is noted for its high thermal conductivity. It is most often used in blow molds, cores, inserts in injection molds, injection nozzles, hot runners, and manifolds. Alro stocks 172 BeCu copper in plate and sheet in various thicknesses and widths.

Cuberyllium's Available Forms for Beryllium Copper (BeCu) Alloy C17200 Alloy 25:

Chemical Composition of Alloy 25 Beryllium Bronze Alloy:

Applications of Beryllium Copper (BeCu) Alloy C17200 Alloy 25:

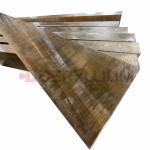

Product Photo of Beryllium Copper (BeCu) Alloy C17200 Alloy 25:

Excellent Properties of CuBe2 Copper Alloys: RFQ: How can I identify high-quality copper alloy products?

Is there a possibility to order customized copper alloys?

What is the delivery time of copper alloys from Cuberyllium?

What are the benefits of using Copper Alloys?

What are the disadvantages of using Copper Alloys?

|

||||||||||||||||||||||||

| Product Tags: Electrical Industry Beryllium Copper Alloy C17200 Beryllium Copper Alloy ASTM Hard Beryllium Copper Alloy |

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |