CW101C Be Cu Bronze Sheet Beryllium Based Metals 10mm 20mm 30mm

|

|

CW101C Be-Cu Bronze Sheet Beryllium-based Metals Sheet 10mm 20mm 30mm

About CW101C Be-Cu Bronze Alloy: Copper Beryllium Alloys are precipitation hardening alloys possessing remarkable strength, elasticity and fatigue resistance and good resistance to corrosion. This makes them ideal for a number of demanding industry sectors such as Petrochemical, Oil and Gas and Mining. The fatigue and elasticity of Beryllium Copper are useful in pressure responsive components such as spring applications. It is also increasingly machined into miniaturised components, required by Electronics and Telecommunication manufacturing for everyday items such as mobiles, laptops and tablets. The principal compositions consist of around 1.6% to 2.0% Beryllium, with a small addition of Cobalt to refine grain size. We can supply these alloys can in the following forms: i) Solution treated (Annealed), or

Properties of CW101C Be-Cu Bronze Alloy: Fast Heating & Fast Cooling

Typical Physical Properties of CW101C Be-Cu Bronze Alloy:

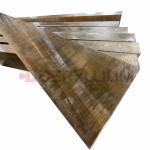

Product Photos:

FAQ:

By the physical shape, the proper analysis, and the correct mechanical values.

Different copper alloys are tested for a very long time and always

applicable to individual demands.

Usually with 7-10 working days, it will depend on the final qty requested by customers.

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.

Copper Alloys can be more susceptible to corrosion, particularly oxidation. which can impact it suitability for some applications. |

||||||||||||||||||||||||||||||||||||

| Product Tags: CW101C Be Cu Bronze Sheet 10mm Bronze Sheet 30mm Bronze Sheet | ||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |