C71200 Beryllium Copper Plate Thin Sheet Polished

|

|

C71200 BERYLLIUM COPPER PLATE Copper Thin Sheet Bronze Sheet Plate

About CUBERYLLIUM ®: Cuberyllium is a factory specialized on Bronze Alloy Products for

more than 20 years.

Beryllium Copper Alloy Introduction

Typical Applications of C71200 BERYLLIUM COPPER ALLOY: Applications(C17200)

Typical Physical Properties of C17200 Beryllium Copper:

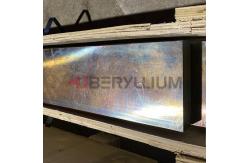

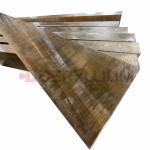

Product Photos:

Why choose Cuberyllium Metal for beryllium copper alloy products?

Standards of Beryllium Copper Alloy Grade:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Thin C17200 Beryllium Copper Sheet Polished C17200 Beryllium Copper Plate C17200 Bronze Sheet Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |