Standard Tolerance Beryllium Copper Strips C1720R 0.35mmt X 38mmw

|

Beryllium Copper Strips C1720R-1/2H Size 0.35mmt x 38mmw with Standard ToleranceProduct Normal Description:

Introduction of Beryllium Copper Alloy C1720: Standards: ASTM B196, AMS 4533, SAE J461, RWMA CLASS IV, CuBe2 2.1247 C17200 is also known as Alloy 25 and is the most commonly utilized beryllium copper alloy and is notable for exhibiting the highest strength and hardness compared to commercial copper alloys. Its strength and hardness is similar to that of steel. C17200 copper's ultimate tensile and Rockwell hardness properties in a peak aged condition are in the 200 ksi range and RC 45 respectively (electrical conductivity 22% IACS minimum).

Chemical Composition of Beryllium Copper Alloy C1720:

Tipical Application of Beryllium Copper Alloy C1720:

Standard Tolerance of Beryllium Copper Alloy C1720:

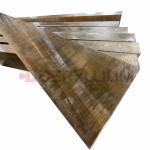

Product Photo of Beryllium Copper Alloy C1720R:

Key Technology of Beryllium Copper(Heat treatment) Age Hardening Age hardening significantly enhances the material’s strength. This reaction is generally carried out at temperatures between 260°C and 540°C depending on alloy and desired characteristics. This cycle causes the dissolved beryllium to precipitate as a beryllium rich (gamma) phase in the matrix and at the grain boundaries. It is the formation of this precipitate which causes the large increase in material strength. The level of mechanical properties attained is determined by the temperature and time at temperature. It should be recognized that beryllium copper has no room temperature aging characteristics. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Bright Beryllium Copper Strips 2T Beryllium Copper Strips Strips C17200 Beryllium Copper | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |