TD04 State Beryllium Copper Metal Strips For Contract Springs

|

|

BE-CU Alloy 25 Beryllium Copper Metal Strips With TD04 (Hard) State For Contract Springs Product Normal Description: Product Name: Beryllium copper metal strips Grade: BE-CU Alloy 25 Standard: ASTM B194, SAE J463, J461 Product Specification: 0.05mmx50mm, 0.05mmx100mm,0.05mmx150mm State: H(TD04) Typical Application: used for microswitch production Product Brand: CUBERYLLIUM®

Applications of BE-CU Alloy 25 Beryllium Copper Metal Strips: C17200 likewise displays extraordinary protection from stress unwinding at raised temperatures. Beryllium copper coil, beryllium copper strip are used in fasteners, electric industry, pump, springs, electrochemical industry etc. We provide high-quality beryllium copper strip with quality assurance.

Chemical Composition of CuBe2/C17200 Copper Alloys (CUBERYLLIUM ®-172): Product Grade: CUBERYLLIUM ®-172(UNS. C17200) Beryllium(Be): 1.80-2.00% Cobalt(Co) + Nickel(Ni): 0.20% Min Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max Lead: 0.02% Max Copper(Cu): Balance Note: Copper plus additions equal 99.5% Minimum.

Typical Physical Properties of CuBe2/C17200 Copper Alloys (CUBERYLLIUM ®-172):

Temper Designations of CuBe2/C17200 Copper Alloys (CUBERYLLIUM ®-172):

Applications of C17200 (CuBe2) Alloy (CUBERYLLIUM ®-172):

Standard Tolerance of CuBe2 Strip C17200 (CUBERYLLIUM ®-172):

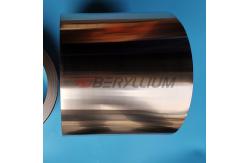

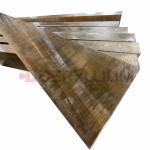

Product Photos:

FAQ: Q1: Could you produce Beryllium Copper strip by Mill Hardened

process. Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®. 2: We are the only one who melting by Vacuum semi-Continuous Furnace. 3: Surface further polishing for top clients. Q3: Why you melting by Vacuum semi-Continuous Furnace. Q4: What's the payment terms? |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: TD04 State C17200 Beryllium Copper Beryllium Copper Metal Strips TD04 State Copper Metal Strips | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |