Beryllium Copper Alloy 25 (UNS C17200/CDA 172) Round Rod By ASTM B196

|

|

Beryllium Copper Alloy 25 (UNS C17200/CDA 172) Round Rod By ASTM B196 Product Normal Description: Product Name: Beryllium Copper Alloy Round Rod Grade: Alloy 25 (UNS C17200/ CDA 172) Standard: ASTM B196 Product Diameter: 8-30mm State: A(TB00),1/2H (TD02), H(TD04),AT(TF00),HT(TH04) Typical Application: used for electrical industry and industrial Product Brand: CUBERYLLIUM®

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: high strength beryllium copper alloys 172(UNS. C17200),173(UNS. C17300),170(UNS. C17000), and copper alloys selected for high conductivity 751(UNS. 17510),750(UNS. 17500),741(UNS. 17410). We also Supply Master alloy : CuBeryllium-200, CuBeryllium-275, CuBeryllium-350 and Cuberyllium-400 to global factory.

Chemical Composition of Beryllium Copper Alloy 25 (UNS C17200/CDA 172): Product Grade: CUBERYLLIUM ®-172(UNS. C17200) Beryllium(Be): 1.80-2.00% Cobalt(Co) + Nickel(Ni): 0.20% Min Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max Lead: 0.02% Max Copper(Cu): Balance Note: Copper plus additions equal 99.5% Minimum.

Typical Physical Properties of Beryllium Copper Alloy 25 (UNS C17200/CDA 172):

Mechanical and Electrical Properties of Beryllium Copper Alloy 25 (UNS C17200/CDA 172) Round Rods:

Industrial Application of Beryllium Copper Alloy 25 (UNS C17200/CDA 172):

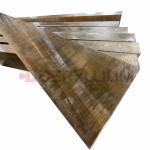

Product Photos:

FAQ: Q1: Could you produce Beryllium Copper strip by Mill Hardened

process. Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®. 2: We are the only one who melting by Vacuum semi-Continuous Furnace. 3: Surface further polishing for top clients. Q3: Why you melting by Vacuum semi-Continuous Furnace. Q4: What's the payment terms? |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Alloy 25 C17200 Beryllium Copper Beryllium Copper Alloy Round Rod ASTM B196 C17200 Beryllium Copper |

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |