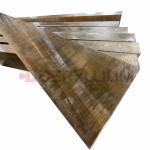

Copper Beryllium Strip UNS. C17200 (CuBe2) 0.28mm x 100mm State XHM

Product Normal Description:

Product Name: Copper beryllium strip

Grade: UNS. C17200 (CuBe2)

Standard: ASTM B194, SAE J463, J461

Product Specification: 0.28mmx100mm

State: XHM

Product Brand: CUBERYLLIUM®

Chemical Composition of Copper Beryllium Alloys UNS. C17200 (CuBe2):

Beryllium(Be): 1.80-2.00%

Cobalt(Co) + Nickel(Ni): 0.20% Min

Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max

Lead: 0.02% Max

Copper(Cu): Balance

Note: Copper plus additions equal 99.5% Minimum.

The principle characteristics of alloy 172 are an excellent

response to precipitation-hardening treatments, excellent thermal

conductivity, and resistance to stress relaxation. The high

strength beryllium coppers C172 can be purchased in the solution

annealed or cold worked tempers and can be easily formed or

machined. A low-temperature heat treatment (600 degrees for 2-3

hours) produces maximum strength and hardness. C17200, also

commonly known as Alloy 25, CuBe2, is available in round rod, bar,

tube, strip, and wire.

| CuBe2(C17200) Strip Application: | Electrical |

|---|

| Fasteners |

| Industrial |

| Connectors, contacts |

| Bushings/bearings for aerospace industry |

| Oilfield drilling collars and instrument housing |

| Springs |

| Rugged resistance welding gun structural components |

| Plastic injection molding and metal diecastings |

Typical Physical Properties of Copper Beryllium Alloys UNS. C17200 (CuBe2):

| Density (g/cm3): | 8.36 |

| Density before age hardening (g/cm3): | 8.25 |

| Elastic Modulus (kg/mm2 (103)): | 13.4 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): | 17 x 10-6 |

| Thermal Conductivity (cal/(cm-s-°C)): | 0.25 |

| Melting Range (°C): | 870-980 |

Fabrication Properties of Copper Beryllium Alloy UNS. C17200

(CuBe2):

| TECHNIQUE | SUITABILTY |

| Soldering | Good |

| Brazing | Good |

| Oxyacetylene Welding | Not Recommended |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Good |

| Spot Weld | Good |

| Seam Weld | Fair |

| Butt Weld | Fair |

| Capacity for Being Cold Formed | Good |

Product Package of Copper Beryllium Alloys:

Usually we pack the beryllium copper strips on coil, outside is

plywood case.

Key Technology of Beryllium Copper(Heat treatment)

Age Hardening

Age hardening significantly enhances the material’s strength. This

reaction is generally carried out at temperatures between 260°C and

540°C depending on alloy and desired characteristics. This cycle

causes the dissolved beryllium to precipitate as a beryllium rich

(gamma) phase in the matrix and at the grain boundaries. It is the

formation of this precipitate which causes the large increase in

material strength. The level of mechanical properties attained is

determined by the temperature and time at temperature. It should be

recognized that beryllium copper has no room temperature aging

characteristics.