CuBe2 C17200 Beryllium Copper Strip Thickness 0.28mm With State XHM

|

|

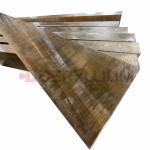

CuBe2(C17200) Thickness 0.28mm Beryllium Copper Strip With State XHM and Hardness 300~360HV Product Normal Description: Product Name: Beryllium copper strip Grade: CuBe2(C17200) Standard: ASTM B194, SAE J463, J461 Product Specification: 0.28mmx100mm State: XHM Product Brand: CUBERYLLIUM®

Chemical Composition of CuBe2(C17200) Beryllium Copper Alloys: Beryllium(Be): 1.80-2.00% Cobalt(Co) + Nickel(Ni): 0.20% Min Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max Lead: 0.02% Max Copper(Cu): Balance Note: Copper plus additions equal 99.5% Minimum.

The principle characteristics of alloy 172 are an excellent response to precipitation-hardening treatments, excellent thermal conductivity, and resistance to stress relaxation. The high strength beryllium coppers C172 can be purchased in the solution annealed or cold worked tempers and can be easily formed or machined. A low-temperature heat treatment (600 degrees for 2-3 hours) produces maximum strength and hardness. C17200, also commonly known as Alloy 25, CuBe2, is available in round rod, bar, tube, strip, and wire.

Typical Physical Properties of CuBe2(C17200) Beryllium Copper Alloys:

Temper Designations of CuBe2(C17200) Beryllium Copper Strip:

Product Package of Beryllium Copper Alloys: Usually we pack the beryllium copper strips on coil, outside is plywood case.

Why Choose Us? 1, We are a professional beryllium copper alloy manufacturer, with more than 20 years' experience. 2, With various types of beryllium copper alloy, such as beryllium rods, bars, strips, wires and so on. 3, Good quality. 4, Competitive offers. 5, After-sale service. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Thickness 0.28mm Beryllium Copper Strip State XHM Beryllium Copper Strip Strip C17200 Beryllium Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |