UNS C17200 Beryllium Copper BeCu Tape TD04 For EMI Shielding Finger

|

|

UNS C17200 Beryllium Copper BeCu Tape TD04 for the manufacture of EMI shielding finger Product Normal Description: Product Name: Coil copper Grade: Cube2/C17200 Standard: ASTM B194, SAE J463, J461 Product Specification: 0.8-2mm Thickness State: 1/2 H(TD02), H(TD04), A(TB00) Typical Application: used for EMI shielding finger Product Brand: CUBERYLLIUM®

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: high strength beryllium copper alloys 172(UNS. C17200),173(UNS. C17300),170(UNS. C17000), and copper alloys selected for high conductivity 751(UNS. 17510),750(UNS. 17500),741(UNS. 17410). We also Supply Master alloy : CuBeryllium-200, CuBeryllium-275, CuBeryllium-350 and Cuberyllium-400 to global factory.

CUBERYLLIUM ®-172 also named Cube2--UNS. C17200 (CDA 172) Beryllium Copper is the most commonly utilized Copper Beryllium alloy and is notable for its highest strength and hardness compared to commercial copper alloys. C17200 alloy contains appr. 2% of beryllium and achieves its ultimate tensile strength can exceed 1360Mpa, while the hardness approaches Rockwell C45. Meanwhile, the electrical conductivity is a minimum of 22% IACS in the fully aged condition.C17200 also exhibits exceptional resistance to stress relaxation at elevated temperatures.

Chemical Composition of CUBERYLLIUM ®-172 Beryllium Copper Alloys: Product Grade: CUBERYLLIUM ®-172(UNS. C17200) Beryllium(Be): 1.80-2.00% Cobalt(Co) + Nickel(Ni): 0.20% Min Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max Lead: 0.02% Max Copper(Cu): Balance Note: Copper plus additions equal 99.5% Minimum.

Typical Physical Properties of CUBERYLLIUM ®-172(Beryllium Copper Strip C17200):

Temper Designations of CUBERYLLIUM ®-172:

Fabrication and Heat Treatment of CUBERYLLIUM ®-172 Beryllium Copper Alloys: Machinability The machinability rate of C17200 copper alloys is 20%. Welding Welding procedures such as butt welding, seam welding, spot welding, coated metal arc welding, gas shielded arc welding, brazing and soldering are recommended for C17200 copper alloys. For this type of alloys, oxyacetylene welding is not recommended. Forging Forging of C17200 copper alloys is carried out at temperature ranging from 649 to 816°C (1200 to 1500°F). Hot Working C17200 copper alloys have good hot working property. Cold Working C17200 copper alloys have excellent cold working property. Annealing C17200 copper alloys are annealed at temperature ranging from 774 to 802°C (1425 to 1475°F).

Standard Tolerance

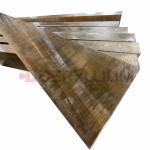

Product Photos:

Applications of CUBERYLLIUM ®-172: CUBERYLLIUM ®-172 is usually used for electrical industry, fasteners and industrial. Electrical Industry: electrical switch and relay blades(switch parts, relay parts), clips, fuse clips, connectors, spring connectors, navigational indstruments, contact bridges, belleville washers; Fasteners: washers, lock washers, fasteners, retaining rings, roll pins, screws, bolts; Industrial: pump parts, springs, electrochemical, spline shafts, non sparking safety tools, flexible metal hose, housings for indtruments, bearings, bushings, valve seats, valve stems, disphragms, springs, welding equipment, rolling mill parts, valves, bourdon tubes, wear plates on heavy equipment, bellows.

FAQ: Q1: Could you produce Beryllium Copper strip by Mill Hardened

process. Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®. 2: We are the only one who melting by Vacuum semi-Continuous Furnace. 3: Surface further polishing for top clients. Q3: Why you melting by Vacuum semi-Continuous Furnace. Q4: What's the payment terms? |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 0.02mm C17200 Beryllium Copper Tape C17200 Beryllium Copper EMI Shielding Finger C17200 Beryllium Copper | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Tensile Strength Copper Alloy Sheet Ribbon 590 - 660Mpa |

|

Heat Treating Beryllium Copper C17200 BE Bronze Round Bars 10mm 20mm 30mm |

|

Dia 4mm Beryllium Copper Round Bars CuBe2 For Resistance Welding Electrode |

|

RWMA Class 4 C172 Beryllium Copper Wiring TD03 Or TD04 Temper |

|

Tempers Rwma Class 4 Beryllium Copper Alloys Astm Standard Bright Polished |

|

Berylco 25 Material Beryllium Copper Plates 12x41x1000mm Formats |