HYDRAULIC SCRAP METAL STEEL CONTAINER BOX TYPE SHEARCONTAINER TYPE SHEAR FOR CUTTING SCRAP METALS

metal shear is applicable for cutting the metal shaped in different cross section like round,

square, channel, angle, I shape, plate and various waste structural

metal at cold state. It brings convenience to the baling, storage and transporation of

scrap metal materials, also offers qualified furance charge for

smelting plant. With large application range, this machine is

commonly used as the processing equipment in the metal recycling

unit, casting room of factory and machinery construction industry.

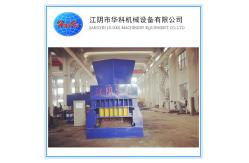

Box shears, also known as horizontal shears, are a new type of

shearing equipment that can process large amounts of scrap metal.

Due to the continuous progress of society and the continuous

increase of labor costs, operators are increasingly eager to save

resources and improve efficiency, which prompted the birth of box

shears.

Our shear has speeder, when unload, one cylinder will drive the

main shearing cylinder to move, with more than 50% faster speed,

save more than 30% time.

ADVANTAGES ;

1. Low operating cost, high efficiency, no pre-gap, less operation,

and continuous feeding.

2. The self-enclosed operation is fully controlled by PLC, which

greatly improves the work efficiency.

3. Loading and transportation by towing vehicles.

4. Small size, integrated type, high stability.

5. The box shear can be controlled by an engine.

6. Low investment and operating costs.

7. All inner surfaces of box shears have a wear plate cover, so

there is less wear.

8. The waste material is added from above, and the waste material

is compressed by the pre-compression cylinder

and automatically slides down and is sheared by the shearing

cylinder. This design greatly improves the efficiency and safety of

the equipment.

HYDRAULIC SCRAP METAL STEEL CONTAINER BOX TYPE SHEAR

PARAMETERS:

CONTAINER TYPE SHEAR FOR CUTTING SCRAP METALS

Contact us! We would like to tell you more about our shearing

system.

| Item No. | PARAMETERS | REMARKS |

| 1 | SHEARING CYLINDER | Model | YG340/220-870 | Travel length | 870mm | 250tons *2=500 tons |

| | | Nominal

Thrust | 2500X2kN | Quantity | 2 | |

| 2 | MATERIAL HOLDING CYLINDER | Model | YG240/160-890 | Travel length | 890mm | 125tons pressure |

| | | Nominal

Thrust | 1320KN | Quantity | 1 | |

| 4 | Material Box Dimension(L×W×H) | 2200×1400×400 mm | |

| 5 | Hydraulic system working pressure | 25MPa | |

| 6 | Hopper size | 2200X1400(mm) | |

| 7 | Cutting length/maximum holdling range | 1400mm / 450mm | |

| 8 | Total power | 75kW | |

| 9 | Power specification | 380V/3PH,50Hz | |

| 10 | Cutting angle | V shape+9 degrees | |

| 13 | maximum cutting range

Δb≤450Mpa | Round steel:φ150mm | FROM MIDDLE PISITION OF THE BLADES |

| | | Square steel bar:100×100mm | |

| | | Steel plate:40×600mm | |

| 14 | Shearing frequency | 2-3times/minute | |

| 16 | Machine outer size | 6000×2220×3550mm | |

| 18 | Oil tank volume | 3500 litres | |

| 20 | Electric Motor | Model | Y225M-6 | Rated power | 45 +30KW | |

| | | Rated speed | 970 rpm | Quantity | 1+1 | |

| 21 | Hydraulic pump | Model | HY250/YCY160 | Rated Pressure | 31.5MPa | |

| | | Nominal

Displacement | 250ml/r/160ml/r | Quantity | 1+1 | |

RELATED PRODUCTS ALSO HOT SELLING :

Some other high efficiency scrap shearing machines that people are

buying :

Ganry type heavy duty scrap metal shear with big material box:

https://youtu.be/KW6k9f6CRMc