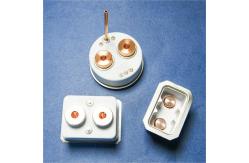

Antaeus Custom Advanced Relay Ceramic Assemblies Metal Brazed Contactor Ceramic Parts

|

|

Wholesale Antaeus Custom advanced relay ceramic assemblies metal brazed contactor ceramic parts

1. Description: This product is developed and produced by Antaeus, it has obtained the national invention patent with patent number ZL201410316175.3 and Chinese utility model patent with patent number ZL20152104226.1. It uses high-purity toughened alumina ceramic with thick film nickel plating , suitable for brazing different materials such as copper and alloy, and can meet both seismic and tensile requirements, and it is also resistant to high current and arc impact, It meets the reliable sealing and insulation standards of DC high-voltage relays. Now it is an excellent technical solution in the field of new energy vehicles and DC high-voltage electronic control.

2. Advantages: - High precision and good air tightness for sealing - Easily brazing with kovar and copper components directly - Outstanding hermetic sealing with hydrogen gas filling, 100% hellium leaking tested - Good insulation, anti-magnetic, static electricity-free character - Excellent magnetic quenching capability for high votage and large current - Excellent thermal shock resistance and good thermal stability - Outstanding strength and toughness for 200K life cycles - Complying with CE, CQC, ROHS and REACH regulations - Reliable quality, Non-toxic, healthy material, Eco friendly - Professional R&D team is available for your requests of various vacuum ceramic components

3. Pictures 4. Technical Parameters:

5. Process Flows: Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Inspecting --- Packing

6. Application Fields: New energy vehicles, charging station, solar power generation, energy storage and power storage system, electric vehicle power system ,and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices: Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter 9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service 11. Shipping and Package: 12. Our aimed market:

Loudi Antaeus Electronic Ceramic Co.,Ltd is located in China, and it is a manufacturer and international supplier of advanced technical ceramic products since 2004. Our customer base, which includes many Fortune 500 companies. The Company has developed a wide range of ceramic and assemblies that are used in various industries such as new energy vehicles. Antaeus Ceramics is equipped with state-of-the-art manufacturing facilities and technical expertise to develop and supply ceramic components as per customer design and specifications. Our high performance ceramic products made from al2o3 Alumina, Zirconia,among others finds wide application in various industries that requires high temperature resistance, chemical resistance, wear resistance, electrical insulation or mechanical strength.

Customized are welcome according to your drawings or samples.

FAQs:

Q4:What is your Capacity? A:300,000 pcs per day; A: About 15-35 days,according to the quantities required;

Q7: Is it available to provide customized products?

Notes:please feel free to contact us for more details when you have any inquiry!

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Antaeus Ceramic Assemblies Metal Brazed Contactor Ceramic Assemblies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Energy Vehicles Alumina Ceramic Components 3.82g/Cm3 Ceramic To Metal Assemblies |

|

Customized Industrial Alumina Ceramic Components For Oxygen Sensor |

|

Relay Aluminium Oxide Ceramics Housing Brazing Ceramic To Metal Assembly 3.6g/Cm3 |

|

High Hardness Alumina Ceramic Components Products For Electric Vehicles Relay |

|

Factory ISO9001 Automobile Relay Parts Assemblies Alumina 95 Ceramic Housing Components |

|

95 Industrial Aluminum Oxide Ceramics Brazed Ceramic To Metal Impact Resistance |