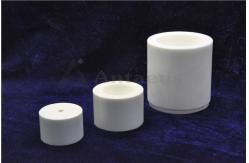

High Compressive Strength Alumina Ceramic Components 99.5% HRA85

|

High Compressive Strength Alumina Ceramic Components 99.5% HRA851. Description: The easiest time to machine alumina ceramic is before the process of sintering, during what is called a “green state”. Machining during this stage of the process allows easy machining into different complex geometries, but machining at this stage is not always possible, depending upon the part shape, size and intricacy, and because of the further shrinking of the part during the sintering process.---That is why professional alumina ceramic manufacturing companies usually machine alumina after sintering using high-quality diamond-coated tools. These tools help abrate the material away until the desired form of alumina ceramics is created.---This type of machining process will guarantee that alumina ceramic will retain precise dimensions after machining. However, alumina is hard and tough, and this process tends to be expensive and time-consuming.---That is why it is important to partner with a company that injection molds alumina to near net size in large quantities. This will help reduce overhead costs, helping you receive a lower price for alumina advanced ceramic components and products of an equally high quality. 2. Feature Advantages: 1) High elasticity modulus 2) High compressive strength. 3) Anti corrosion 4) Abrasion resistance 5) Impact resistance 6) High precision 7) High stability 8) Good advanced ceramic materials 9) High welding sealing performance 10) High hardness and high density 11) Low thermal conductivity 12) Chemical inertness 13) Good wear resistance 14) High Fracture toughness 15) Good insulation performance 16) High temperature resistance 17) A variety of specifications is available 18) Satisfy various technical requests 19) Lower medium spoilage 20) Stiffness texture 21) Widely apply for automotive ceramic sensor , ceramic heater ,electric heating

3. Material Features / Properties:

4. Technical Parameters:

5. Process Flows: Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Inspecting --- Packing

6. Application Fields: New energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices: Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter 9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service 11. Shipping and Package: 12. Our aimed market:

Loudi Antaeus Electronic Ceramic Co.,Ltd is a full service manufacturer of advanced ceramic components and assemblies to customer specification. Our products include high purity alumina oxide ceramics for new energy vehicles, zirconia and machinable ceramics. Antaeus's focus is on providing cost effective solutions to wear and corrosion problems in a wide range of applications and industries. We specialize in precision toleranced industrial ceramic components in both prototype and production quantities. Since 2004 Antaeus's advanced ceramics have enabled thousands of customers to solve problems and develop products and processes that would not have been possible with conventional engineering materials. Antaeus is a leader in providing advanced ceramics solutions for new energy vehicles battery worldwide.Our customer base, which includes many Fortune 500 companies.

Application: These Advanced technical ceramic components find application in a number of industries, some of them being sealing technology, pumps, wire-drawing, battery/ cell manufacturing, sand-blasting, chemical, electronics, textile, automotive, etc. Customized are welcome according to your drawings or samples. FAQs (Frequently Asked Questions)

Q4:What is your Capacity? A:300,000 pcs per day; A: About 15-35 days,according to the quantities required;

Q7: Is it available to provide customized products?

Loudi Antaeus Electronic Ceramic Co.,Ltd Factory address:Loudi Economy and Technological Development Zone,Hunan,China. Contact person:Alice Deng Tel:+8615073852630 (wechat) Mail: alice@andidz.com Skype: alicedeng0629 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: HRA85 Alumina Ceramic Components 99.5% AL2O3 Alumina Ceramic Components High Compressive Strength Al2o3 Ceramics | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Energy Vehicles Alumina Ceramic Components 3.82g/Cm3 Ceramic To Metal Assemblies |

|

Customized Industrial Alumina Ceramic Components For Oxygen Sensor |

|

Relay Aluminium Oxide Ceramics Housing Brazing Ceramic To Metal Assembly 3.6g/Cm3 |

|

High Hardness Alumina Ceramic Components Products For Electric Vehicles Relay |

|

Factory ISO9001 Automobile Relay Parts Assemblies Alumina 95 Ceramic Housing Components |

|

95 Industrial Aluminum Oxide Ceramics Brazed Ceramic To Metal Impact Resistance |