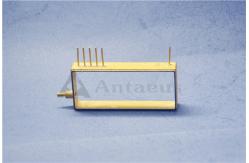

ISO Pressing Alumina Ceramic Components Ceramic To Metal Brazed Assembly

|

|

Alumina ceramic components / relay ceramic assemblies / ceramic - metal brazed contactor

1. Description: 1) ISO pressing --- ISO pressing is a forming process where our in house spray dried material is used to fill a mold and then compacted at around 20,000 PSI. ISO pressing is used to create blanks of certain sizes and shapes that cannot be easily formed by dry pressing or the extrusion process. These blanks can then be machined green or in the bisque state. 2) Bisque --- Bisque alumina is material that has been pressed or compacted into shape and then is partially fired. This enables the material to become harder than “green” material but not as hard as fully fired alumina. Bisque firing allows the material to be machined using conventional methods and tooling. Once bisqued, the material has a hard chalky feel to it. Bisque material can be used to create prototypes or one off parts. Once the part is complete, bisque alumina can be fully fired to achieve a harder, fully dense part with all the properties of alumina. 2. Feature Advantages: 1) High elasticity modulus 2) High compressive strength. 3) Anti corrosion 4) Abrasion resistance 5) Impact resistance 6) High precision 7) High stability 8) Good advanced ceramic materials 9) High welding sealing performance 10) High hardness and high density 11) Low thermal conductivity 12) Chemical inertness 13) Good wear resistance 14) High Fracture toughness 15) Good insulation performance 16) High temperature resistance 17) A variety of specifications is available 18) Satisfy various technical requests 19) Lower medium spoilage 20) Stiffness texture 21) Widely apply for automotive ceramic sensor , ceramic heater ,electric heating

3. Material Features / Properties:

4. Technical Parameters:

5. Process Flows: Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Inspecting --- Packing

6. Application Fields: New energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices: Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter 9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service 11. Shipping and Package: 12. Our aimed market:

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ISO Pressing Alumina Ceramic Components Brazed Assembly Alumina Ceramic Components Ceramic To Metal Brazed Assembly | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Energy Vehicles Alumina Ceramic Components 3.82g/Cm3 Ceramic To Metal Assemblies |

|

Customized Industrial Alumina Ceramic Components For Oxygen Sensor |

|

Relay Aluminium Oxide Ceramics Housing Brazing Ceramic To Metal Assembly 3.6g/Cm3 |

|

High Hardness Alumina Ceramic Components Products For Electric Vehicles Relay |

|

Factory ISO9001 Automobile Relay Parts Assemblies Alumina 95 Ceramic Housing Components |

|

95 Industrial Aluminum Oxide Ceramics Brazed Ceramic To Metal Impact Resistance |