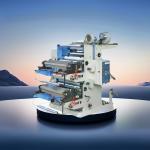

RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine

|

|

RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine

Support and Services:RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible

packaging materials Unit Type Flexo Printing Machine Technical

Support and Services We provide technical support and services for RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine. Our team of experienced technicians and engineers are available to help you with any questions or issues you may have. We offer a wide range of services such as installation, maintenance, troubleshooting, and repairs. In addition, we offer training and consulting to ensure that your machinery is running at its best. At our facility, we provide a full range of services for RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine. Our team of technicians and engineers are available to help you with any questions or issues you may have. From installation to maintenance, our team is fully equipped and ready to assist you. Our goal is to provide the best technical support and services for RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine. Our team of experts is available to answer any questions or concerns you may have. We take pride in providing quality service, and we are committed to ensuring your satisfaction. Packing and Shipping:Packaging and Shipping RY-B-6 Color-1000mm Roll paper(30-260g/㎡) and other flexible packaging materials Unit Type Flexo Printing Machine is packaged carefully to ensure it arrives safely and in excellent condition. The machines are fully assembled, and then wrapped in film then packed with the fumigation wooden box. Machines are shipped via air or sea freight, depending on the customer’s preference. FAQ:Q: What is the Brand Name of RY-B-6 Color-1000mm Roll

paper(30-260g/㎡) and other flexible packaging materials Unit Type

Flexo Printing Machine? A: The Brand Name is Supreme. Q: What is the Model Number of RY-B-6 Color-1000mm Roll

paper(30-260g/㎡) and other flexible packaging materials Unit Type

Flexo Printing Machine? A: The Model Number is RY-B. Q: Where is the Place of Origin of RY-B-6 Color-1000mm Roll

paper(30-260g/㎡) and other flexible packaging materials Unit Type

Flexo Printing Machine? A: The Place of Origin is China. Q: What is the Certification of RY-B-6 Color-1000mm Roll

paper(30-260g/㎡) and other flexible packaging materials Unit Type

Flexo Printing Machine? A: The Certification is CE. Q: What is the Minimum Order Quantity of RY-B-6 Color-1000mm Roll

paper(30-260g/㎡) and other flexible packaging materials Unit Type

Flexo Printing Machine? A: The Minimum Order Quantity is 1. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

SLITTING CUTTING AND REWINDING MACHINERY KRAFT COATED LAMINATED SILICON GLASSINE OFFSET PAPER CUP PAPER BAG 15-500GSM |

|

B-1600 HIGH-SPEED SLITTING MACHINE UNWINDING:3 INCH AIR SHAFT SHAFTLESS WITH 3-6 ADAPTER REWINDING:3 INCH SLIP SHAFT 2PC |

|

YT SERIES TWO-COLOR FLEXOGRAPHY PRINTING MACHINE POLYETHYLENE, POLYPROPYLENE BAG, CELLOPHANE AND ROLL PAPER PACKAGE BAG |

|

YT-PT FLEXO PRINTING MACHINE 6COLOR 1000MM STRAIGHT GEAR TYPE FLEXOGRAPHIC PRINTING MACHINE EXPORTED CONFIGURATIONS |

|

YTGS FLEXO PRINTING MACHINE STACK TYPE 120M/MIN Ø1200MM UNWINDING AND REWINDING DIAMETER SYNCHRONOUS BELT TRANSMMISSION |

|

RY-940 PAPER CUP FLEXO PRINTER IR OR UV DRYING ASYNCHRONOUS SERVO MOTOR MORE STABLE AND POWER IMPORT STEPLESS INVERTER |