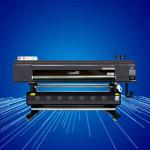

1/300 Inch 8 Rows 3200 Nozzle Sublimation Inkjet Printer

|

|

Sublimation Inkjet Printer Printhead Original I3200 - A1 Printhead For Eps on The Eps on 4720 printhead (or EPS3200 as it is also known) is a new piezoelectric nozzle introduced by Eps on in recent years , the main technical parameters of Eps on 4720 printhead are basically the same as Eps on 5113 printhead.The difference is that the 5113 can only be used with water-based ink , while the Eps on 4720 is corrosion-resistant , suitable for ink, such as water , oil , solvent , UV , dope , heat sublimation, etc. , it is a multi-purpose sprinkler head .

Sublimation Inkjet Printer Printhead Feature Of Eps on I3200 - A1 1. PrecisionCore Technology a. All MEMS manufacturing and thin film piezo element can realize high precision and high density(600 npi / 2 rows of nozzles). Contributes to compact, high speed, high quality, and high image quality. b. Precision made of Eps on unique MEMS nozzles and an ink flow path ensure the per fectly round ink droplets are placed accurately and consistently. 2. Support for grey-scale Eps on's unique Variable Sized Droplet Technology (VSDT) delivers smooth gradation by freely control to eject the droplet volume. 3. High resolution Ink ejection of up to 4 colours realize with high resolution (600 dpi/colour). In addition to the I3200, I1600 has also been added to the lineup in order to meet the various customer needs. 4. High durability PrecisionCore print head has proven high durability and extended service life by Eps on's industrial printers.

Inkjet Printer Printhead Eps on I3200 - A1 Parameters

Printer Printhead Eps on I3200 - A1 Sizes Nozzles(mm) External Dimensions

Printhead Maintenance 1. Printhead in your printer, if you don’t use it in short time, you should cleaning head in every 2 or 3 days. When you cleaning the head, please printing the head test first and make sure it’s state is normal, because we should ensure the capping core and head is sealed well. 2. Printhead is not in your printer, if the time within 2 days, just put head in the box and needn’t cleaning. 3. Printhead is not in your printer for a long time, you need cleaning at least 2 times. Doing second cleaning after 12 hours when finished first cleaning. Ensure the head has been cleaned well and then inject the protection liquid into the head and put it in the box to storage.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 3200 Nozzle Sublimation Inkjet Printer 8 Rows Sublimation Inkjet Printer 1/300 Inch Sublimation Inkjet Printer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

I3200-A1 Fedar Textile Inkjet Printer |

|

4720 Sublimation Inkjet Printer |

|

FD70-2/FD70-4 Sublimation Inkjet Printer A3 Tshirt Dtf Printer |

|

Impresora Multifuncional Sublimation Paper Inkjet Printer Fedar FD5198E |

|

Fedar Sublimation Inkjet Printer 1.9m Print Width Cloth Printing Machine |

|

Fedar 8 Printheads Sublimation Inkjet Printer For Cloth Print |