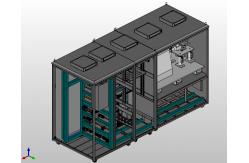

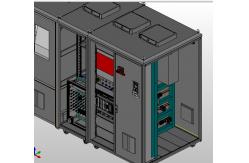

SSCD12-1000/4500 12kW 115Nm Diesel Engine Performance Test Bench System

|

|

Product Description

The three cabinets are spliced to form a total cabinet, which is convenient for disassembly and combination. It is internally divided into five functional zones: Measurement and control system area, data acquisition area, engine bench area, oil supply and fuel consumption measurement area, smoke exhaust area. Composition of dynamometer cabinet: dynamometer, coupling, external cabinet, protective cover, engine, engine mounting bracket, flat plate, shock absorption and smoke exhaust.

Working Principle

Its working principle is to invert the AC power from the AC power dynamometer into DC power through the DTC inverter and then invert it into AC power for grid connection; the DTC frequency conversion inverter system adjusts the power grid current of the power dynamometer to control the speed and torque of the prime mover . For example, when used together with the XLE1000 series measurement and control system produced by our company, it can not only accurately measure and control the speed and torque of various rotating power machinery, but also can control the temperature, pressure, flow, current, voltage, etc. Parameters are measured and controlled.

Automatic Test Function

The automatic experiment function means that after the user specifies the test series and test-related parameters on the software interface, the software will actively control the working state of the dynamometer according to the pre-set experimental steps and combined with the real-time working conditions of the equipment obtained during the experiment. How the experiment works. The automatic experiment process does not require human operation, and all control and data collection and analysis are completed by this software.

SSCD12-1000/4500 electric dynamometer technical parameters

Technical Parameters

Benefits At a Glance

System Application

The engine comprehensive performance test bench is mainly used to test the fuel consumption of the engine; output torque, output speed, output mechanical power; emissions, exhaust gas analysis; temperature rise, vibration, noise, etc. It can carry out type test and factory test to evaluate the comprehensive performance of the engine, and provide accurate parameter basis for engine development, production, maintenance and field application. The engine comprehensive performance test bench can test all kinds of diesel engines, gasoline engines, etc. The test process can be loaded manually or automatically, the test results can generate customized test reports, curve charts, etc., the process data can be generated in Word, Excel, or PDF format files, and the data can be saved, edited, and printed. The test system interface is simple, easy to upgrade and maintain. The company trains the operating personnel free of charge to provide guidance for use and maintenance. Users can choose test items according to specific requirements:

Company Profile

Seelong Intelligent Technology (Luoyang) Co., Ltd. is a high-tech enterprise specializing in equipment measurement, control, design, manufacturing and sales of power engineering systems in various fields such as aerospace, automobiles, and new energy. The company is located in the beautiful Peony Flower City - Luoyang, the capital of God.

The main products are electric dynamometer, torque sensor, measurement and control system and condition guarantee system and other products. Establish a complete sales service system, adhering to the business philosophy of quality for survival and service for development, to provide users with power engineering measurement and control solutions in various fields.

Company Certificates

Packaging and Shipping

FAQ

|

||||||||||||||||||||||||||||||||

| Product Tags: Diesel Engine Performance Test Bench System 12kW Engine Test Dynamometer | ||||||||||||||||||||||||||||||||

|

120kW 0.05%FS Measurement Accuracy Gasoline Engine Electric Dynamometer Test Bench System |

|

45kW 143Nm Rated Speed 3000rpm Gasoline Engine Electric Dynamometer Test Bench System |

|

90kW Max Speed 9000rpm Customizable Gasoline Engine Performance Evaluation Electric Dynamometer Test Bench System |

|

60kW Max Speed 8000rpm Customizable Gasoline Engine Performance Evaluation Electric Dynamometer Test Bench System |

|

SSCD300-1500-3200 High Torque Measurement Accuracy Low Maintenance Diesel Engine Electric Dynamometer Test Bench |

|

SSCG30-2500/9000 30kW 95Nm ±0.2%FS High Accuracy Low Maintance New Energy Engine Test Bench System |