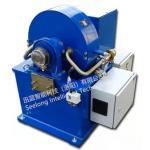

Automatic Control 31Nm 10KW Eddy Current Dynamometer

|

|

SECD10-3000/15000 easy operation eddy current dynamometer

Principle of operation

When the current flow through the field coils, then magnetic field is produced. If the toothed rotar is rotated in the field, the magnetic flux changes and eddy current are produced in the end wall of cooling plate. These Eddy Currents buildup an opposite magnetic field and decelerate the rotar. The braking torque is transfered via the bearing mounted body to the load cell. The dynamomemter load is regulated by changing the excitation current. Energising Coils: The coils are fully encapsulated in two pieces. These are insulated from the main body with high quality insulating material. This gives very optimum distribution of flux throughout the working area. Because of this in case of low speed torque it gives best results of air flow from the center of dyanometer. This features ensures rapid response of reliability under the serveral loading conditions. Control: The power absorbed by the dynamomemter is controlled by varying the energising current at the field coil. System is provided with Closed Loop Control by giving feedback signal from Load Cell for Torque & from RPM Sensor for Speed. Both & Automatic Control Systems are provided along with PC based Data Acqusition & Control System.

Product picture

Characteristic curve

Technical parameters

Product discribtion

Typical application

|

| Product Tags: 10KW Eddy Current Dynamometer Automatic Eddy Current Dynamometer |

|

SECD440-1500/6500 High Precision Eddy Current Dyno |

|

SECD260B-1800/7500 1.3 Inertia Eddy Current Dynamometer |

|

SECD260-1800/7500 Water Cooling Eddy Current Dyno |

|

SECD150-1500/6500 High Braking Torque Eddy Current Dynamometer |

|

522Nm Single Rotor Eddy Current Brake Dynamometer For Slewing Ring |

|

Self Monitoring 50KW Eddy Current Dynamometer In Engine |