48 Heads 100ml 3.5KW Bottled Water Filling Machine

|

XP-HYGZ 48-48-20 Washing,Filling And Pressing Integrated Machine For Liquid Production LineProduct Description Overview

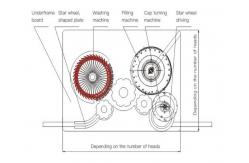

The washing, filling and turning integrated machine is mainly used for washing (water washing or air washing),filling, cap turning (capping) and sealing of oral liquids, syrup, medicinal wine, health products and tincture for external use in such industries as medicine, food, health products, etc.

Features

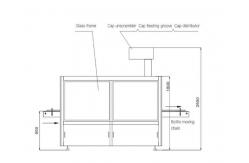

-Integrating bottling washing, filling and cap turning (capping) and taking small floor space, it is suitable for equipment upgrading in old plants. -The linear turning bottle inverting device is adopted for bottle washing. The bottle is inverted for a longer time so that residual water is easy to remove. It can be equipped with an ultrasonic washing device to ensure clean bottles. Both water washing and air washing are acceptable.

-With servo driving, the filling volume is adjusted on the man- machine interface. Each pump is driven by a set of servo motor, and a set of servo motor can also drive many pumps.

-It adopts the plunger metering pump to fill liquids of various viscosities with high precision. The pump can be easily disassembled, making cleaning and sterilization convenient. It can be equipped with CIP/SIP cleaning and sterilization system.

-The filling principle also includes the use of peristaltic pump, negative pressure type, weighing type, self-flow type, reflux defoaming type, etc.

-PLC control system with variable frequency speed control and high degree of automation.

-The filling system is provided with the anti-leaking device, realizing filling from the bottom of the bottle, rising slowly and avoiding bubbles.

-The tightness of the air gripper type cap turning head can be adjusted without damaging the bottle and cap. It can be equipped with servo motor driving with adjustable torque. The capping head adopts flexible design with easy adjustment, and can also b© designed to be used for pull caps.

-It can be equipped with the cap storage and lifting mechanism and the mechanism for identifying reverse caps and eliminating nonconforming products.

-The whole machine is suitable for various specifications of bottles and adjustments can be completed conveniently within a short time.

-The whole machine is designed according to GMP requirements.

Main Technical Parameters

About us

-Listed company founded in 2003(WINLONG GROUP CORPORATE) -17 years’ manufacturing experience in the aseptic filling production line. -Exclusive manufacturing factory of 20,000 square meters (Changzhou, Jiangsu) -More than 100 famous enterprise business partners across China. -Expanded global business network -Proven design, efficient and reliabile products. -Customized design to meet the customer’s demand.

Our Services and Warranty

1.We can customize the machine as customer required.

We can customize with your packaging materials, production capacity and demands. We will provide you with associated design solutions and case videos.

|

||||||||||||||||||||||||||||

| Product Tags: 3.5KW bottled water filling machine 100ml bottled water filling machine 100ml juice filling machine | ||||||||||||||||||||||||||||