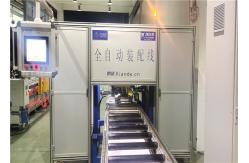

Customized Busbar Inspection Machine 2 Axis Middle Position

|

|

Grounding / Insulation Test Automatic Busbar Inspection Machine

Copper Busbar Bending Machine Heat dissipation hole The small opening on the device is conducive to satisfying the isotropic heat dissipation in the box and giving full play to the role of heat dissipation. Cable middle joint protection box To prevent the voltage from being unstable and causing damage to the circuit and plc of the equipment, the equipment has a protective effect when the voltage is unstable. Emergency protection button The equipment has safety protection technical measures such as reliable grounding, residual current protection (leakage protection) 30mA 0.1S, anti-misoperation foot switch, and out-of-control protection (emergency stop).

Busbar production equipment Kehinde is specialized in manufacturing and customizing busbar production machines including manual production line, semi-automatic production line, automatic production line, automatic inspection machine, automatic packaging machine, automatic mylar forming machine, automatic mylar slitting machine, profile cutting machine, busbar processing machine, gas hydraulic press machine, joint bar processing center, welding robot, elbow production machine, NC position fixture and other machines related to busbar processing.

Introduction

Automatic Busbar Inspection Machine is composed of three parts, feeding positioning station, inspection station and discharge station. When the busbar enters the feeding position, the control system will select the right testing fixture to start testing from the information identified by bar code or previous assembly line. Three tests will be performed including HV withstanding test, insulation resistance test and grounding test. After test is finished, testing report will be generated. This report can be saved, printed on site and recorded remotely. Its format can be set according to customer’s requirements. Automatic inspection machine is mainly used for batch inspecting on the straight busbar. Elbow busbar type shall be tested on manual inspection machine.

|

||||||||||||||||||||||||||||||

| Product Tags: customized Busbar Inspection Machine 2 axis Busbar Inspection Machine Middle position Busbar Inspection line |

|

Automatic Inspection MachineBusbar Short Circuit Withstand Insulated Inspection Machine For Busduct |

|

Automatic Busbar Equipment For Wrapping Film Over Busbuct Away From Dust |

|

Short Circuit Withstand Busbar Inspection Machines Automated |

|

1000mm Busbar Short Circuit Withstand Insulated Inspection Machine For Busduct |

|

Automatic Busbar Packing Machine For Wrapping Film Over Busbuct |

|

Busway Production Machine For Wrapping Film Over Busbuct Away From Dust |