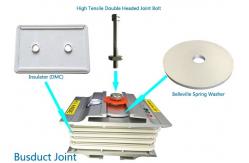

Double Head Grade 10.9S Busbar Joint Torque Bolt with Galvanized

|

|

Double Head Grade 10.9S Busbar Joint Torque Bolt with Galvanized

Features

Installation Guideline Of Busduct Joint Step2: Align and connect both busduct terminal with joint stack connector. Step3:Joint stack stopper acts a guideline to ensure a full contact surface of the overlapping conductors. Step4: Tighten the double headed bolt by using socket wrench untile the outer head shear off. Step5:Place joint pack covers on both sides of the busduct joint section and tighten all the bolts and nuts with socket wrench.

|

||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 10.9S m12 bolt torque ISO9001 Busway Torque bolt ISO9001 m12 bolt torque |

|

Bus Plug stab finger Copper Conductor Link For Busbar In Tap Off Box |

|

PA 66 Busbar Plug for Compact Busduct tap off unit for power |

|

High Adhesive Busbar Temperature Thermal Indicator Sticker On Busbar Joint |

|

Clinching Accessories Steel Rivets For Busbar 5x8mm |

|

Aluminum Casting Capped End Insulation Plate Supporting Busbar |

|

Aluminum Conductor Busbar Joint Systems Connection One Bolt Design |